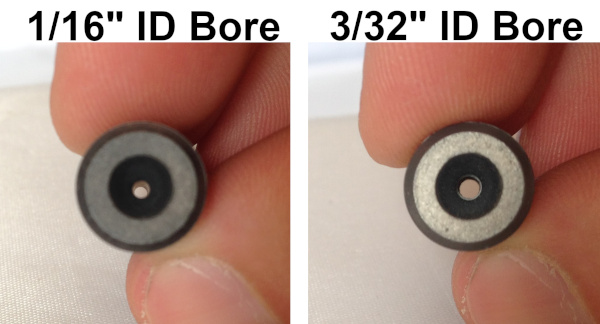

If you’re using a smaller nozzle tip with an inner diameter (ID) bore size 1/16″ or 3/32″, you are most likely using a pressure port sandblaster.

These sizes aren’t as common for general contractors since they have a smaller output so many of the charts online don’t list the specifications of air compressor requirements.

The small 1/16″ & 3/32″ ID sizes are actually great sizes for use inside blasting cabinets and are common for sandblasting glass. Since many of my subscribers & I work in this field, I wanted to update the calculated specifications for these sizes. Please see the below chart:

Pressure Pot Air Requirement Chart (SCFM)

| Pressure (PSI): | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 120 |

| 1/16” nozzle | 1.5 | 2 | 2.5 | 3 | 3.5 | 4.5 | 5.5 | 6.5 |

| 3/32” nozzle | 3.5 | 4.5 | 6 | 7 | 8 | 10 | 12.5 | 15 |

* 4 SCFM = 1 compressor horsepower

Rough Guide & How to Use

The chart provides a rough guide to find a sufficient air compressor that meets your desired PSI for your nozzle ID size.

For example, if you were using a 3/32″ nozzle and wanted to blast at a consistent PSI of 80, you would need an air compressor that can output 10 Cubic Feet per Minute (CFM). Since 1 compressor horsepower usually outputs about 4 CFM, you may need an air compressor with roughly 2.5 horsepower.

We have also updated the main chart with specs for all common nozzle sizes here: https://www.sandblasterinfo.com/air-compressor-chart/