If you sandblast in industries utilizing the larger sandblasting systems with a large nozzle such as the C1 tip, you may want to consider using the tungsten carbide version which is known as the TC1 nozzle. This is a high quality, long lasting nozzle that can replace the C1 which is used in our large 3/4″ ball valve nozzle assembly.

Benefits of using the TC1 nozzle tip vs C1

- Lasts up to 20-30 times longer than ceramic C1

- Retains ID bore size for longer periods of time which ensures high blasting pressure output consistently

- Reduces air compressor fatigue due to slower ID bore wear

- Lower cost per hour of use

Disadvantage of using TC1

The only disadvantage of the TC1 carbide nozzle is it is considerably heavier and higher in cost. The TC1 weights roughly 18 ounces verses the C1 which weights about 4-5 ounces.

Manufactured by Kennemetal

Kennametal is a manufacturer of some of the best sandblasting nozzles in the industry, among other items. This large nozzle uses top wear grade carbide with durable construction which reduce the likelihood of breaking when accidentally dropped.

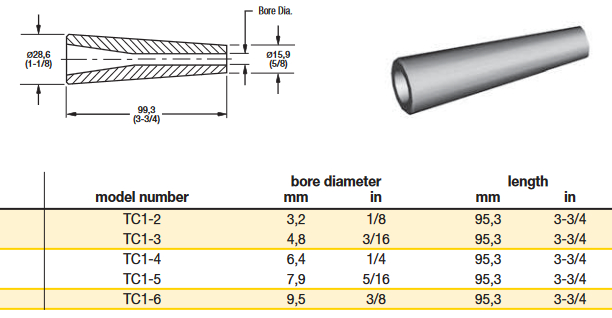

Selection of ID Bore Sizes

We offer the ID bore sizes, from smallest to largest: 1/8, 3/16, 1/4, 5/16, 3/8. (see this chart for help determining a bore size)

Order Online

Reduced Price here: $122.99

International Orders from Countries Outside the United States

If you live outside the United States, you must select the option below for the additional shipping costs involved.

Do you plan on having these mad in 3/32″?

@Stephen , not at the moment but will consider this size. The 3/32″ isn’t currently manufactured by Kennametal. However, we do supply the Type 1 with a 3/32″ with the ceramic material.

how do i order

@anthony perkin, I probably should make the checkout cart more user friendly. I now have a Cart checkout page at the top right of the page that you can go to after clicking Add to Cart.