Example of the 3/32″ ID bore.

We are now offering the tungsten carbide TL2 Series sandblast nozzle tips, manufactured by Kennametal.

These are a bit more affordable than their ROCTEC nozzles which we offer, but still hold up for a longer duration than most tungsten carbide nozzle brands. No other tungsten carbide comes close to the high-quality and performance as these.

Note: not all carbide nozzles last the same duration. In fact, we are still trying to improve our carbide tips. Although these may cost a bit more than others, they last longer than several tips from other brands so they can save money in the long run.

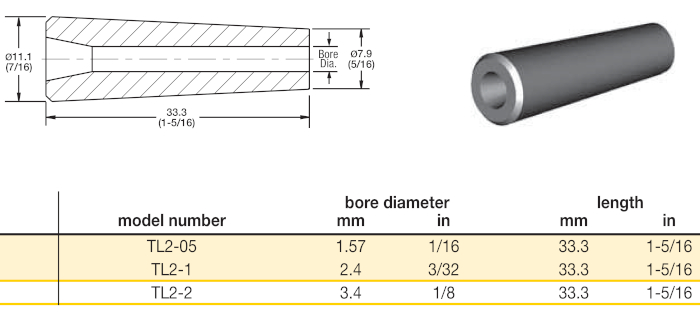

TL2 Series Details:

- 7/16″ OD tapered to 5/16″ OD

- 1-5/16″ Length

- High-Density Tungsten Carbide- made from the highest quality materials and compacted for a heavy, 30 grams weight providing superior wear resistance.

- Kennametal estimates their tungsten carbide to last 500-800 hours with steel grit, 300-400 hours with slag and 20-40 hours with aluminum oxide abrasive.

Sizes:

Select Inner Diameter Bore from:

- 1/16″ ID (Smallest for finer abrasive grits)

- 3/32″ ID (Medium size grits is our most popular)

- 1/8″ ID (Largest bore offered for courser grits)

(See this chart for help determining a bore size)

As a distributor for Kennametal, we are offering some of the lowest prices for a limited time. Other stores charge up to $62 with shipping. Order below and checkout with secure Paypal.

Reduced Price here: $36.99

International Orders from Countries Outside the United States

If you live outside the United States, you must select the option below for the additional shipping costs involved.

I work in fused glass and have some sandblasting equipment. I have a booth and a pressure pot. Problem is my compressor is too small, 110, 2hp, SCFM 5.7 @ 90 PSI. I don’t have 220 where my blasting room is. I have had some limited results with small things. I would like to add sandblasting to my work for a matte finish but I’m not ready to go to the expense of running 220 and upgrading the compressor. I think if I can get what I have to work at the best of its ability I will learn a lot about the process of which there is a lot to learn. Right now I am focused in getting a balance of flow from the pressure pot.

@Michael, my suggestion would be to possibly use a smaller inner diameter (ID) nozzle tip size so that it doesn’t consume too much air and have a good output.

Thanks for the information. I will try that. I will order the 1/16 carbide tip. The carbide tip seems like it’s worth it because it’s long life. I have to replace the 23″ air bypass line on my pressure pot. I went everywhere in Santa Fe looking for one, I couldn’t find it anywhere. I’ve ordered a 4 FLEXILLA 3/8 ID 1/4 ENDS from from TPTools, I think it will work, hoping. Looks like I have ordered the 4′ not the 2′. It should arrive tomorrow and I should be able to start up. I have several tips right now and I’ll use the smallest one and see how it goes. I’m looking into upgrading my compressor, not sure if it is worth the investment at this point.