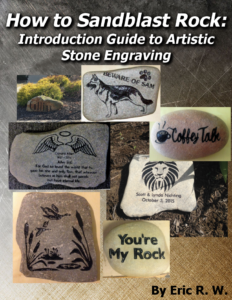

Download my new ebook to learn how to sandblast rocks and access the course here.

This involves the process of creating designs into stone. What you do is cut out a stencil from a resistant rubber or vinyl material and blast the area until it cuts a desired depth. Have you ever seen those large rocks in people front yards with their address marked in it?

Well, this is all done by blasting the rock and is better known as sandcarving. I talk a little bit about this in the sandblaster plans, tips, and information manual that I wrote up. The top thing that you need to know is that a pressure pot sandblaster is required to carve the stone because it has high pressures that is needed to get the job down.

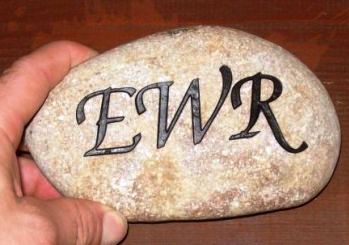

Shown below is an small example of a stone that I found in a nearby river.

What I did was just cut out a stencil and blasted over the stencil on the rock with about 90 psi (from what I remember). After that, you can spray paint the carvings to highlight the deep markings like I did. I used a black spray paint but you can use your creativity with different vibrate colors.

Please leave any comments below or any questions. Thanks and hopefully I can get some more information up soon.

Hi Eric,

I’m considering building the pressure pot that you have designed. How do you rate your unit next to one of the cheaper Harbor Freight units. I’m just starting out and will probably use the pot for general rust cleaning. Love your site. Thanks

Not sure if you got my plans, but as stated there- I like the home made one better. It seems to work better and I think its because the inside of the tank is smooth unlike the HF model.

The only problem with my blaster/ plans is it doesn’t have a safety plug. Thanks!

Lots if great timely info, interested in learning as much as i can about sand carving and glass etching. And the stencils to use with them. Thanks for your emails with helpful info so far.

just wondering if you use the vinyl mask and if so how do you get it to stick well to varying stones.? My brother has a giant sandblasting booth we intend to try this with but have no experience except with wood, any tips or suggestions? Thank you, DAVE

i am gonna be sandblasting granite benches and bluestone is the 100lb eastwood tank with aluminum oxide a good choice if not any recomendations?

How do I even get started and what tools do I need and what kind of media and what kind of material to draw the stencil on?

i was wondering what kind of sand or material thats the best for granite?

What equipment would I need to sandblast rock (sand carving)? I mostly would like to do river rocks and possibly bone. I am a beginner.

Hi Jim, the most essential thing is a pressure pot sandblaster. Then just need some thick sandblast resists to make stencils.

I would like to sandblast river rock for wedding favors. Can you recommend the necessary tools I would need please. Just writing letters on river rock for 100 guests. Thanks so much !

What size compressor is needed to fill a pressure pot sandblaster? Also will a Roland 24 be good enough to cut the stencils?

Thank you in advance for the information.

I have a siphon blaster, not a pot. Is it still possible to carve stone with it? I tried it with my compressor at 150 psi and my vinyl stencil didn’t hold up for an instant. Does anyone know how thick a material I need for a vinyl stencil?

I bonded the stencil to the uneven rock with drywall corner adhesive. since the PSA on the vinyl wasn’t strong enough to h0ld it in place. Could that have been part of the reason the stencil didn’t hold up?

@ Dan- it is possible to siphon but not recommended because it will take much longer to do and eat up your compressors air too much. Best to get a pressure pot.

Most people use about 30 mil thick stencil.

The Carving was really wonderful. Keep it up.

Sources for vinyl without having to order the expensive stuff on line ?

I have the sandblasting system and would like to due stones. Just basic like names and addresses on smaller nothing to large to handle by hand. My issue is were to find the stenciling precut or reasonable pricing stencil to cut by hand. what is the best can not afford the 1000 plus dollar printers that i find.

Great comments and questions! I would love to know the answers. I am just starting out with this medium and am anxious to learn all I can.

Thanks.

What is used to keep the stencil on rock to sandblast

I have the stencil 15 mil that recommended but do I need ahesive to help it stay on the river rock to sandblast so it want come off

Hi Eric

You real reminded me the job did of writing school name on concrete it was on September 9th-10th 2010 at Rushey Green School Culverley Road London SE6 2LA using blasting machine grit and metal plate that was written the school name was able to write the name which will be there forever this is my testimony to what you said.

Hi Eric

Firstly thanks for your site. Some really useful information.

My wife wants to frost glass, in particular jam jars. She has a business and would like to

offer the jars with candles in to use in the garden. Frosting spray is useless in the inclement weather. So I thought of sandblasting them. Is something I could do? If so what equipment would you suggest?

Best wishes

Matt (U.K)

@ Matt, if she just wants to etch the surface, any sandblaster would do. Just use a good abrasive that you can reuse like aluminum oxide.

I am interested in the scm sandblaster by David Horn. Why are you selling. Just curious. Is there any problems with the dust getting out. I read where one person complain about dust clouds it was on the better business burea. I was wondering if you experience anything like that.

What’s the safest media to use? I am also a beginner.

Super information. Haven’t tried sandblasting rocks yet, but am gearing up to do so. Have media ready and waiting, and have a nice collection of river rocks from a local river. Sandblasting is just amazing. Can’t believe how clean, crisp, and deep the designs are. I’m a novice and already seriously hooked. :)

SQ

I am interested in blasting rocks later. Once I get the equipment. What type of media. On another site they recommend silica but I am concern of the safety of the silica . What do you think. I was going to use some sort of grit or like aluminum oxide.

dont even bother with cheap sand… aside from it being bad for ur health, it is soft and wont carve near as fast as aluminum oxide. actually alum oxide barely even does anything to most hard rock. alum oxide is much more expensive so u will need to contain it. i portioned off a section of my garage with plastic to make a blast room. sweep your floor clean before you blast and you will be able to use ur grit over and over again. or use a blast cabinet if possible. use 80 or 150 grit. also you will need a tungsten carbide nozzle 1/8 inch. forget the cheap ceramic nozzles. they last about an hour.

Help? My father is creating a memorial son to place in a meadow where my son wrecked his car. We have a large rock that was pretty rough so we were instructed to grind/polish where we wanted to place the stencils for sand blasting. We ground a center portion and were polishing when someone snuck over to “help” (my dad was complaining about how long it was taking to get it smooth) and begin to polish the outer edges that my dad wanted to be natural. How do we fix this? (My dad has been crying for two days).

So you’re saying this someone polished the outer edges when he didn’t want them polished? I would think it would weather over time…. but it will be a long time. Maybe you could chip/chisel the face of the rock to get a rough look…. I don’t know just trying to help.

Hi from Cherry Hill NJ

I have a 4x3x4 feet. granite Boulder that I like to engrave. I like to know if anyone know someone that can travel to my place to engrave this stone. Thanks! 856-313-2708

David

hey gentlemen, first thank you for offering your experience…much appreciated! I have had interest in sandblasting stone (sandstone, granite, etc.) for a long time but have no experience either in equipment needed and use of the equipment. I do have experience with rubber stencil design and cutting.

what type of compressors would you recommend (hsp, gl, psi)? please note I don’t have a bank roll.

what type of nozzle/set up would be advisable?

economic yet long lasting. is this a fantasy?

any wisdom appreciated.

brian

hey ladies and gentlemen,

thanks for sharing your experience, you are appreciated. I have wanted to sandblast and sandblast sculpt stone for a long time but have no experience, other than rubber template making.

I would like to buy a compressor and nozzle, etc. but don’t know where to begin.

how many: psi, gl, and hsp would I need in a compressor to accomplish my goal?

what sort of nozzles or nozzle/hose set would be appropriate?

I don’t have an unlimited bank roll but it costs what it costs. lowes or harbor freight budget.

economical and long lasting…if possible?

thank you.

brian

thanks

I’ve gotten into this sandblasting rock within the past year and made good money with it, but i’ll tell you right up front…. If you want to avoid a lot of frustration, borrow the money and get a decent setup from the start. I can guarantee you it will pay for itself. I’m not talking about those $5-6k kits from SCM. I’m sure they’re great, but some of the stuff you won’t use, at least not right away. Here’s what i’m using…. Then i’ll tell you what i would like to upgrade to as soon as i can afford it.

Equipment i have now……

-Pressure pot sandblaster from “Rayzist Photomask” in California -$1100

– Comes with a Tungsten Carbide 1/8″ nozzle which is very important.

-Aluminum Oxide Abrasive

-old air compressor that produces somewhere around 12-14 CFM at 50 psi

-Homemade air dryer, plus the air dryer that came with the pressure pot

-Blast room – plastic curtains- about 12 x 18 ft. with window and fan blowing dust out

-Overhead hoist

-Magnum force stencil cutter from SCM $2400 or so.

How?

-Sandblast at 40-55 psi- no need to go much higher.

-Wear a mask! That stone dust is harmful!

-You could probably use a cheaper pressure pot using the plans on this website to modify it, but you will need a tungsten carbide nozzle. Ceramic nozzles on the cheap blasters wear out with aluminum oxide in maybe an hour. Tungsten Carbide lasts maybe 40 hrs.

What i wish i had….

– Bigger air compressor… at least 24 cfm. would like 35 cfm but then i need 3 phase electricity

– along with bigger air compressor, I could go to a 3/16″ nozzle and about double my productivity

– Bright lighting

-One o those good fancy sandblasting helmets with a big lense

-More time to do it! I love the end product!

Some good info here!! I would really like to see some of the follow ups to these comments. I’m trying to figure out grit size to tip size. Any ideas??

again eric…thank you for all your wisdom and assistance. love this site! I am ready to buy my compressor. you once emailed me a letter sent in by another member. unfortunately I had a virus in the computer and it was erased. I remember 80 gl, cfm14-15 (??) and 150 psi (??). I have interest in sandblasting stone (sandstone, granite, etc.).

what if I bought a Lowes: 5-HP 80-Gallon 155-PSI 230-Volt Vertical Electric Air Compressor. 16.1 SCFM at 90 PSI easily runs high air consumption tools such as sanders and grinders; 155 max PSI so you can operate a wider range of tools and maintain longer run time? do you have another suggestion less than $1,000?

also what rubber stencil products and thickness should I use?

what type of nozzle/set up would be advisable? what type of sand/aluminum oxide would be best?

any wisdom appreciated.

brian

Air compressor sounds great. Use 80 grit aluminum oxide grit- non other will even work on hard rock. SCM Systems has the stencil you will need. 42 mil rubber with adhesive on one side. Comes in like a 30 ft roll, 15″ wide. Read my other posts above for more info.

I was wondering what size blaster and what type media is used to break granite and rock for tombstones? I have used number 4 sand with an industrial blaster on the few that I have done. I was told that may not be the best thing to use. I need a portable blaster.

Break Granite? you mean engrave it? Are you talking about engraving tombstones?

Hi Rich,

May I know the composition of the stencil, and how hard or soft?

we use a material called resist, we get a design we want to carve on the rock and send it to a graphic artist who carries resist and then they put the design on the resist. we press to the stone and the material used to blast the rock does not burn through it, like a regular stencil would.

It is amazing what you are doing, you have really create a tribe here, I have a Skat Blast Cabinet, a Campbell-hausfeld AT122601 Gun and a C801H Husky 80 gal. 3 Cylinder Single Stage Electric Air Compressor 16.1 CFM at 40 PSI and 14 CFM at 90 PSI. I need to buy a 180Grit Silicon Carbide to get the results I need in Porcelein and Marble, I am going to use this grit size because I also want to be able to use it in Glass and Acrylic.

1. Do I need any special nozzle with x diameter in order to use Silicon Carbide?

2.What Vinyl mm should I use? 3 or 10 to scarve in porcelein, I really want a deep result…

Thank you very much, keep the great work

I want to do sand blasting/etching for smaller material, mostly using polished slabs. Designs would be fairly fine detailed, and not likely larger than 2″-3″ diameter. I do want to be able to etch fairly deeply (at least 0.5-0.8mm). Having never done any sand blasting before, I have some specific questions:

1) Materials used will vary fairly widely in hardnesses (jaspers, petrified wood, possibly some jade), I’ve read through previous comments about using AlOx 80 grit abrasive, and am wondering if I should go with something finer for the smaller detail work I want to do.

2) What kind of pressure am I going to need for fine detail work like this? Still in the 90 psi range that seems to be recommended for larger work?

3) I’m assuming if I use AlOx, I need the tungsten carbide nozzle, regardless of other factors. Is the 1/8″ others are using for courses work going to likely be too large, or should it be good?

4) Stencils – What thickness and material can I get away with? I was looking at 12 mil vinyl material, which obviously would erode too quickly for the course work many others are doing, but for this fine work, would it be durable enough? If not, what thickness would you guys suggest?

5) Has anyone used anything like the Silhouette or Cricut machines for cutting out stencils in vinyl? Any pros or cons about specific machines that you could give?

i want deep etching work for granit stone

sand blasting or another equipments by using best result for engraving work

Hi Eric,

Greetings from Cornwall, Great Britain.

I am keen to source equipment for sand carving and have found myself looking at a vast array of different sandblasters and cabinets – I have the uv light box, resist material, designs and an array of materials and stone to etch. What would you recommend as a start up package to get me going please?

Many thanks,

Davey

I would appreciate any advice on what might be sourced in the UK that you could recommend please.

Many thanks,

Davey

I SEE TONS OF QUESTIONS AND NO ANSWERS….AM I MISSING SOMETHING???

@Rainey and everyone, I apologize for the delay in answer questions. I will be putting together material that explains this further. thanks

Revived mail of sandcarving really it is good news but please tell how much deep it carve and what will be the cost of equipment and carving cost, main thing is cost of production in INDIA

There is one of the manufacture SCM but it is very experience it is not in my budget how get and from can you can provide. I know this your hobi but I am very much impress with your research that is helping to me I am 60 years old but I want to do with the help with you and after that my son can work on it later he will earn with it .

Ok i need to know what type of a compressor I need to sandblast art work in to stone . I have a A..L.C pressure pot 40 LBS . I also have a vinyl cutter/ plotter to cut my stencil on . So any Help ? . I have seen SCM jet stream what kind of set up do they have and how can i do it for less money ? Thank’s