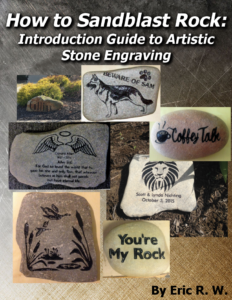

Download my new ebook to learn how to sandblast rocks and access the course here.

This involves the process of creating designs into stone. What you do is cut out a stencil from a resistant rubber or vinyl material and blast the area until it cuts a desired depth. Have you ever seen those large rocks in people front yards with their address marked in it?

Well, this is all done by blasting the rock and is better known as sandcarving. I talk a little bit about this in the sandblaster plans, tips, and information manual that I wrote up. The top thing that you need to know is that a pressure pot sandblaster is required to carve the stone because it has high pressures that is needed to get the job down.

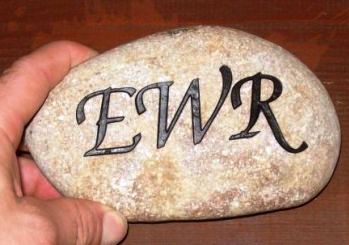

Shown below is an small example of a stone that I found in a nearby river.

What I did was just cut out a stencil and blasted over the stencil on the rock with about 90 psi (from what I remember). After that, you can spray paint the carvings to highlight the deep markings like I did. I used a black spray paint but you can use your creativity with different vibrate colors.

Please leave any comments below or any questions. Thanks and hopefully I can get some more information up soon.

What kind of vinyl will form to & stick to stones & brick?

Not using Vinyl for the stone ! Using Vinyl cutter to cut the sandblast Mask !

Joe kind of compressor do you use two stage or single stage ?

I tried to stick vinyl to the stone but it comes out with pressure. Any glue I can use?

Great question , I also have no luck in sticking vinyl to stone. I would be interested in hearing what might work.

what tickness Resist is needed to blast stone?

what thickness Resist is needed to blast stone?

My question isn’t related to this art L but hopefully you guys can help me. Lately while sandblasting (small stuff) a suction is forming around the gloves putting pressure on my arms. My arms hurt (just a little ache) for a couple of hours after sandblasting. I thought maybe it had something to do with the air filters so I cleaned them but it still persists. I don’t want to wind up with a blood clot or something. Any idea as to what is happening?

Dear Manager,

I’m glad to hear that you are on the market for Stonblast abrasive materials:

Alumina Zirconia, Brown Aluminum Oxide

Sinabuddy specialize in this field with good quality and competitive price.

E-mail me or call me directly, we can talk details.

Best Regards,

Wendy

I do this everyday as my job if your having trouble getting the mask to stick to the stone clean it first with a tack rag then use a heat gun to ensure the mask fits in all the small dints in the stone so no media can get under it

im interested in blasting names on large field stones for farm driveways we are farmers so have all the heavy equipment to move stones my husband is a bodyman he painted cars for 25 plus years so we have a large sand blaster for blasting metal so my question is what size tip do i use for stone and how do i fasten the template to the stone to blast after cleaning away sand can i leave template on to spray colour in the blasted names

I would like to know if there is a mast made for rock carving .. I can’t get the vinyl to stick either!!

It’s hard to come by knowledgeable people for this topic, however, you

sound like you know what you’re talking about! Thanks latahza

What grit would be best

I blasted my first rock today with 70 grit black aluminum oxide using a pressure pot. It etched the river rock quickly and easily. My resist was 12 mil (which was heavier than I think I needed) and I glued it down with woodworking glue. The wood glue held the resist beautifully! Will try 8 mil resist next time which should be a bit easier for my vinyl cutter to cut.

I have presser pot what size air compressor do I need and tips my is 110 PSL thank you tim

@Tim, the grit depends on your preference and how thick your stencil is to hold up to it, but I am currently using 60. At our rock blasting shop, it was courser than that. I am putting together more and more info on this when selecting the right material in the training area and hopefully videos soon too (https://www.sandblasterinfo.com/learn-to-sandblast-rocks/).

To match up a compressor and tip size, you can roughly use this chart: https://www.sandblasterinfo.com/air-compressor-chart/

I am interested in carving text and images into stone, quartz, and granite. I have a regular vinyl cutter but the company I’ve been talking to insists that I use their magnum force cutter (Over $2k) and use their 41 mil vinyl. Is this necessary or can I use thinner vinyl using my graphtec vinyl cutter.

Thank you very much!

Michele, the high quality cutters are usually ideal but they aren’t necessary. Module 2 talks about this.

I’ve tested different materials even with value cutters and you can definitely get away without those high priced cutters. Buying a small roll of different sandmasks to test is a lot cheaper than investing in 2 grand anyway. :)

Pls gave all the details and the materials using the sundblasting and how to used,pls gave the exact materials thanks.

Are air brush sandblaster ok for carving bass relief flowers ..and what would a good sandblaster air gun …cost….I’m an experienced mason from …Perth wa.. western Australia..

where did you buy your sand blasting equipment / where do you find material for stencils

I have the same question as others. I recently started blasting large boulders for a rock company. Being outside, it is impossible to get the rock clean and stay clean to adhere the vinyl. Is there a glue or lite tack to use that won’t affect the color of the stone after peeling off the vinyl?

@Tina, yes an adhesive needs to be used, especially if the rock isn’t smooth like polished granite. Basically, it is rubbed off with a rag and mineral spirits after. We discuss a couple different options that are commonly used.

Many unanswered questions above.

Mainly, what adhesive to use to adhere the vinyl stencil to the surface?

I have a 60 gallon compressor and a sand blast cabinet. I started rock carving using the suction system that came with the cabinet. Worked ok, but I had trouble seeing the work and the suction system seemed to pulsate. So now i have a pressure pot and am not really sure what the setting should be as far as pressure in the pot and at the gun. I can’t really see the grit flowing out of the 3/32″ gun nozzle. any advice or experience would be appreciated. Bob