Note: You can now download my sandblaster plans here.

It seems there has been a lot of people wanting to make a sandblaster themselves and I usually recommended to just buy an inexpensive one such as a Harbor Freight brand.

But lately, I got an email from someone in another country with a different marketplace. I am not aware of the best places to get these from other countries. Also, for anyone’s information, the plans on my site are for pressure pot modifications to fix abrasive flow problems. So if you’re looking to make your own pressure pot sandblaster, I included this video to show you an example of the anatomy of how it’s setup.

So in words, you have a tank filled with abrasive of your choice and it gets pressurized with air. Now Updated: I have now created plans which shows people how to use an old propane tank and weld a top cap on. Its kind of interesting so you might want to read about my do it yourself sandblaster plans here.

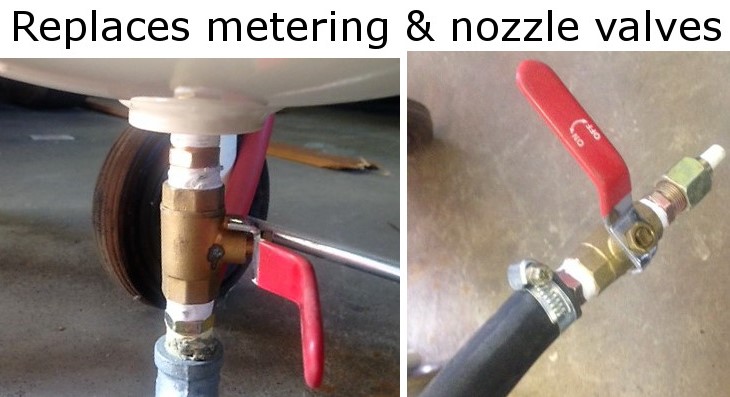

Then an air line splits to the tank and the other half goes to the bottom of the abrasive mixing valve as seen in this picture. Another hose is attached at the other end of the mixing valve with the nozzle at the end. Any questions, just ask below.

Hi Eric

wow this is a very helpful video i really learned from it a lot

now i know how things work and how it was a simple idea

after i watched the video for the first time i started to list items i need (i already get a heavy duty industrial hose)

i think i don’t need any plans now just a clear diagram like this video and a little of creativity

by the way the idea of the engine start plug was very brilliant and new

I am looking forward to purchase the Sandblaster Manual & Fixes soon to prevent any future problems and to achieve the best of it

thank you very much for your concern

i think pretty much its very suitable for my work on the(remove old paint & rust removing) Refurbished sport equipment,please advise me with your opinion

thank you very very much

Gabry

Hey Gabry, no problem and I’m glad I could help! You could try the siphon sandblaster too becuase its much easier to make but it uses up a lot of air. I think I am going to make another post about how the siphon system is setup. Standby and thanks for leaving a comment

-Eric

This was interesting , especially the part about the spark plug. I have a harbor freight siphon blast cabinet. I think I will get along with it for awhile. Something to think about for the people building their own pressure systems from old butane or propane tanks. I do not think I would want to weld on either of those tanks. Where you might end up , you might need someone to carve a stone for you.

I have one more question, where do you get the material to make your stencils out of ?

Thanks,

Dick S.

Richard, there are a bunch of ways to make stencils. You can even use contact paper if your grit isn’t too large. Try searching for sandmasks too- they are used for sandcarving deeper.

welding on propane tanks is easy —trick is fill it with water so nothing there to explode

hello eric this is the first time i write to you and hopefully you can guid me in the right direction am looking to get in to sandblasting heavy trucks and also heavy equipment this will be a mobile sandblaster what i need to know is what size compressor i will need and also what is the best abrisive is best for the job . the compressor that i want to buy is an ingersol rand i thank you for your time hope to hear from you soon mike

hi eric, I have maybe picked you up wrong or misunderstood but im sure you say in your short video –SANDBLASTER PLANS DIAGRAM VIDEO– on you tube via the link with the email you sent that you use a propane tank along with the other various supplies of hardware. the next part is where I am confused, in the text below the video you say ………..”I have seen plans where people use an old propane tank and weld a top cap on. Its kind of interesting so I might try to make one soon.”…….. Is this an old piece of text or a new video cos that looks like an old propane tank and is stated in the video as such. or, as i said before I may have picked something up wrong, could you please clarify this for me thanx stefen

Stefen, yes, you are correct. Thanks for pointing that out.

This is an old post where it had a youtube video provided by someone else making one. I just updated the post (removed their video, and uploaded mine) without realizing the text.

I’ll correct it soon. Thanks. Sorry- that is confusing. I appreciate it

Stefen, its updated now. Thanks for giving me the heads up about this. I miss updates sometimes- I’ve been so busy lately.

Fantastic video and diagram,saved me load’s of cash,well explained .Thank’s again.

Steve from Bonny Scotland

Thank you Steve. If you have any questions, feel free to ask.

hi just watched your pressure pot sandblaster video and its good info but I see a couple comments about engine start plug ? I didnt here mention of it in the video is there an earlier version of the video or later? that I dont have access to, or can you tell me what its about thank you komet

I tried punching out the electrode on the spark plug and also drilling it out,ended up with smashed plugs

@ Komet & Steve, yes it was an earlier version provided by another person. I have since updated it with another (somewhat similar) video except for the part talking about the spark plug used for the nozzle. Sorry, maybe I will create a new post for it soon.

Hi Eric i have a problem with my pot it looks the same as all the rest but the nosel blocks as soon as i start to use it can you help thanks. john

Please read this first (sandblasterinfo.com/nozzle-clogging), along with the page it links to.

Hi Eric.

All I really need a sandblaster for is to make signs on wood… two or three a month … so I do not

want to spend a fortune. I have shown the plan to an engineer mate and he says “no problem”.

Should be ready in a week or so. Will keep you posted on progress.

I normally use a router to make signs (I run a small woodwork shop) and thought could offer a

different and, hopefully, faster alternative.

Bought a syphon gun and a kilo of (black) grit which cost more than the gun. No instructions

but icons indicate it needs a 50lt 3hp compressor which can deliver 6bar (70 psi) . I have one,

so connected up for a test. Nothing happened! (Maybe a tablespoon of grit spat out).

My bigger compressor is a beltdrive V2 3hp 150lt which is used to run my sanders. Hooked

it up to the blaster at 80 psi and … same pathetic result. There seems to be a slight suction

action at the syphon pipe, but not enough to draw up the grit.

There is no blockage in the gun itself.

Any Ideas?

Mike (Cape Town)

P.S. I do like your “personal touch”. Wish you were my neighbour…

Hi Eric.

Thank you for your helpful informatios it´s grat! to people who does´n know anything about sandblast art!

Hi Eric

Come on!!!!!! How wonderful are you when started this career in 1990’s was made to fear about blasting because everything was taught was THIS JOB IS DANGEROUS but now can see that it is but not as has been emphasised.

Now according to your clip what is the maximum pressure should go into the tank and what kind of deadman nozzle and size of hose can be used and can be found?

I real thank you and appreciate for wha you are doing GREAT JOB Eric.

Great info, explains all that is necessary. Therefore enabling the user to identify whats what for this process. Also everyone’s experiences cumulatively bring forth areas to be identified. Thank-You for your time and info on this subject.

as far as air compressor size… i do sandcarving / engraving…..that depends alot on the size of the nozzle you are using. i’m using a 1/8″ tungsten carbide slightly-tapered-bore nozzle and 80 grit aluminum oxide grit at about 45 psi. it uses i’m guessing about 11 cfm. using those big tips you get cheap at the farm store you will go through lots of sand and air. get a smaller nozzle to match your air compressor. but i still think anything under 11cfm wouldnt keep up at 45psi blasting pressure.

I agree with everything Austin said. The only other thing I would add to what he said is that I would highly recommend a “hard” nozzle made out of carbide or harder… You will save money using a quality nozzle if you sandblast more than a few times in the long run. Just do it right!!

Very cool Eric thanks. Now can this be made into a dustless blaster by adding water. Thanks

@Dom, my plans do not show how to make it into a dustless blaster but you can use the idea laid out there to experiment on converting it. I started experimenting on making my own dustless blasting a couple of years ago but haven’t had the time to fully finish it.

What pressure do you recommend stone carving with a anchor stencil?