Miniature sandblasters are just what they sound like. The small sandblasters are made to blast, clean, or erase surfaces lightly. So if you have a small project or are looking to clean a one time project, I don’t blame you if you don’t want to buy expensive sandblasting equipment. These can help save you money because small sandblasters are inexpensive and don’t require a large air compressor either. You can pick up a mini air compressor which will save some money as well. I created a collection of some of the mini sandblasters with links to Amazon where you can buy them below:

Aerosal Sandblaster: The blaster above doesn’t even require an air compressor because pressurized aerosol can supplies the air. Don’t count on it lasting long though.

Paasche Sandblaster Eraser: Paasche is known for creating great mini sandblasters. This is one of their lower priced kits. This is a gravity feed blaster. The only bad thing about it is the small hopper on top.

Large LAC#3 Sandblaster: This is like the previous Passche except the hopper and the nozzle is larger. This can be used for jobs slightly bigger. Its known for cutting faster and has a carbide nozzle tip. This will require more air and a quarter inch air connector.

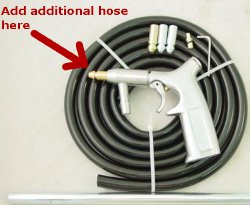

Remote Sandblaster Eraser: (Not recommended: I recently purchased this one and tested it out and it doesn’t work too well.)As far as I know, the remote air eraser from Passche is the biggest mini sandblaster available. The nozzle is separated from the hopper which holds a whole quart. They are connected with a hose and allows you to blast longer while being able to maneuver easily.

Dental sandblaster with cabinet: Another thing to use is a dental sandblaster. These are made for dentists to clean dentures and similar accessories for teeth. However, it can be uses for other industries also. These are a fair price and include a footswitch. There are several brands but listed on Amazon but I believe most of them come from the same manufacturer. You can find other listings here.

Make your own mini pressure pot sandblaster: You can make your own pressure assisted mini sandblaster, if you are up for it. You can see a brief example of making the inexpensive nozzle here and the whole plans here.

Once again all the info. you dig up and send to us is great I think Keep Sending if you would Thanks..

what kind of tip do you want to get for doing glass the one on the top of this page looks like it is just a nozzle..

Hello there, I have bought a LAC #3 sandblaster and was told I could use a mini compressor with it but this only works with the air eraser. What size compressor would I need?

Many thanks!

Once again, the info you put on the web site is good, thanks once again

Thanks for all the info you have sent me Eric, I am in the process of making my first blaster,

I started out with the venturie type gun, but quickly realized that my air compressor would not be able to keep up. As you know, you can only get 4 cfm per horse power of the motor of the compressor, mine is 2.5 hp therefore 10 cfm, as a quarter inch orifice can discharge 104 cfm at 100 psi, it has no hope of keeping up. I have made the pressure pot version out of an old LPG cylinder as in your sketch, and it seems to work well at 75 psi. regards Bob

Bob, thats great. If you want to share pictures of your homemade sandblaster, let me know. Im sure everyone would be happy to see them.

And yes, those larger nozzles can really eat up that air. I always use the smaller nozzles.

Hey I got the plans and built a blaster out of a propane bottle. The first time I used it it plugged up a bit. My fault I should have dumped the junk out of it. Came out awesome. Now if I can just get the sand out of my pants LOL Thanks for all your info

lol Shane and thanks. If you want to share a picture of the finished product, I can post it on the blog.

I am sure everyone would be happy to see it. Let me know

i would like to know more about blasters for car restoration eg pot size and nozzle size

I have a small blast cabinet made of a plastic type material like High Density Polyethylene. It has a .050 ceramic nozzle. Works great for real small stuff. The cabinet is about 18″ square and sits on a table top. Real neat setup. I also have a spot blaster with several rubber cup type end pieces for spot blasting metal or such. The media hits the work and is collected in a bag. No spray to the room. Easy cleanup.

Hi Eric,

Thank you for the valuable blog. I am relatively new to sandblasting, so the information you provide is very interesting and removes the mind boggling aspect of sandblasting.

Currently I am blasting mirrors and glass in a small cabinet(48cmX40cm), however this is a bit restricting. So I decided to build a tool shed and in that tool shed I have started to build a blast room (140cmx160cm). Do you have any recommendations or suggestions which could assist me in this process.

Thanks

Eric, I have a regular size 5HP compressor sandblaster with a pressure pot and cabinet. Do you know of a source from that for: Adapters, Hoses and Nozzles for a Mini Sandblaster and nothing else, like cabinet, compressor, pressure pot, etc.(which would not be needed).

Thank you,

Hugo

Thanks very much for your informative emails. I have a couple of questions for you.

(1) I’ve been researching some options for engraving stone using layered templates. This approach can be expensive requiring some specialized equipment for creation of the template overlays. Do you have any alternative (suggestions) for template creation?

(2) What media/air pressure to you recommend for stripping furniture?

Thanks

Hi Ross, an alternative way is to print out the design to the desired size and using graphite paper to transfer it onto stencil- then cut it out with an Xacto knife. In addition to that, I like to buy adhesive backed paper to print it out on, then lay that on top of the the thicker stencil that is already adhered to your stone. – then cut it by following the lines. There are many ways to do this.

I am assuming you are referring to metal outdoor furniture. I don’t have experience with that but you might want to look at either a soft abrasive like walnut shells/ corn cob or a medium hard abrasive in a finer grit such as crushed glass.

Hi Eric as have said before when started this career never thought such easy ways can be done this is absolutely great news .

Eric,

I saw my last post and I can tell that I didn’t express my question well. Is there an adapter to use the miniature nozzles with the full size pressure pot and hoses, etc? Those little pots don’t hold much sand at all.

Thanks for the information but here one stuggle to get nice blasters for art.

Look like the manufacturers go more for industrial users.

thanks eric- it’s all good… mikey

Great info.

Eric,

Yes I do like this info. I was actually building something much like the LAC #3. As you know, I do mostly Industrial work but tis is great for my home projects!

I have to agree that you really get some good info out. Thanks for providing such a useful site.

Eric, I’m almost ready to start blasting. I am in the early stages of restoring a 1961 MGA, and learning about blasting techniques. Thank-you for all the info you provide. Regards Bill in Delaware.

Can anyone advise where these products can be purchased in South Africa

yes leonard. they have what you need at dee beers diamond mines. go in the office, talk to david.

Eric, SCM Systems sells a “Precision Pressure Pot” with regulator for $995 which seems really expensive. It seems like I could build one for far less. Are you familiar with SCM Systems’ products? Any recommendations?

@ Steve,

I’ve never used their products but from the looks of it, I am sure their products are decent. Though, I have read someone online stating that they didn’t like their equipment- I sorta think it may have been user error.

Other than that, I agree that you can build a mediocre system much cheaper. When I say build, I am referring to either buying lower cost equipment to put together for a system or really building the pressure pot as my plans show. Either works to save money. Thanks

Hi Eric

Thank you for the information. I would like to understand from experienced members, what is the size of the Blaster and also the size of the compressor recommended for wood blasting In a burned house.

I suggest it would take about a week to clean the smoke and soot and maybe 2 days to blast the wood in the attic and walls.

I have never used blaster before.

Hello, thank you for the information you are posting and the comments, very helpful, I have been given a quad bike in a 1000 pieces but complete, so I need a fair bit of sand blasting done, so I’m building a sand blast box from materials I have lying around so far so good, nearly finished, will couple 2 compressors together along with 2 ex LPG tanks. The frame I’m doing the hard way at the moment. Being a retired engineer plenty of time for this project. Keep the info coming its great. Cheers Colin

Your free e-book is the best source in sandblasting information I have found online or anywhere else for that matter. I now have the information I need to buy a compressor and sandblasting equipment I need for my projects. Thank you.