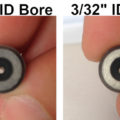

A common question when selecting a sandblaster nozzle is, what inner diameter (ID) bore size should I use? As you may know, it depends on how large of an air compressor you have and the grit size of the abrasive you’ll be using. After you narrow the sizes down that will work according to these specs, the next factor is how large of a blast pattern you would prefer.

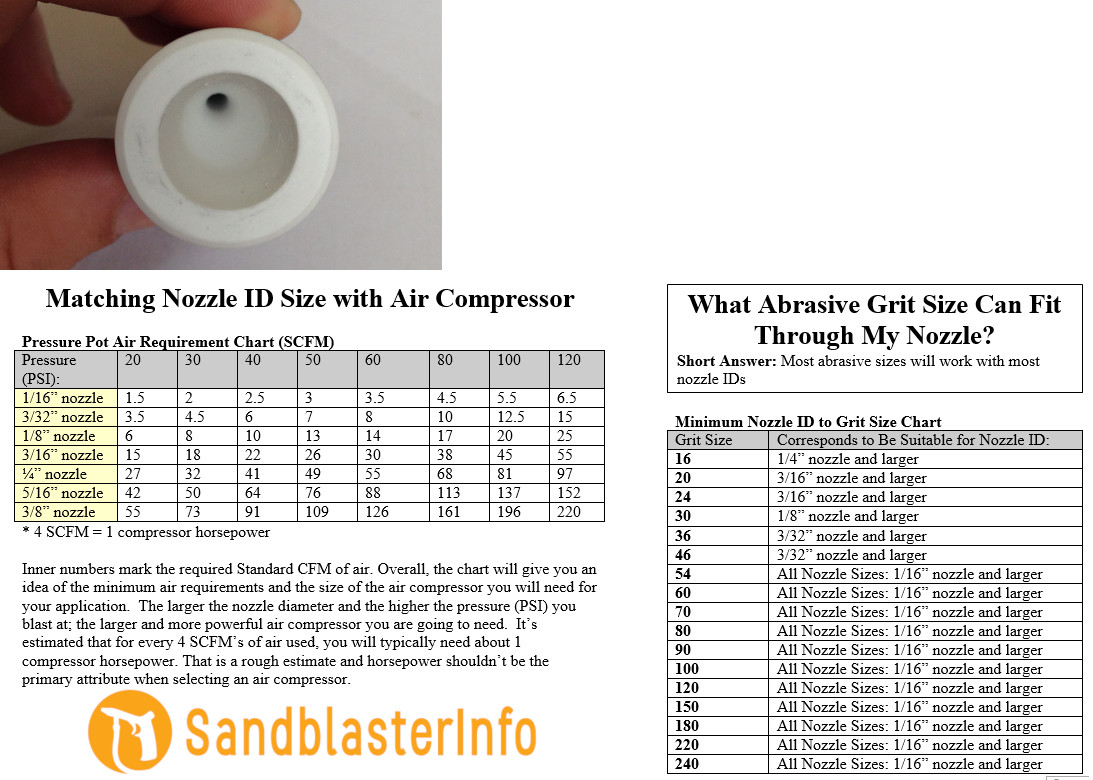

I produced this chart a few years ago and forgot to post it here. This chart is for the pressure pot sandblaster. The explanation on using it is below the chart.

Matching Nozzle ID Bore Size to be Compatible with your Air Compressor Output

To find the bore sizes that will work with your air compressor, you would have to estimate what your highest preferred blasting pressure will be.

Then you would match up the output of Cubic Feet per Minute (CFM) your air compressor is capable of. So you would follow this process:

- In the chart, you would just select the column with the PSI you desire to operate at.

- Find the row within that column that has your air compressors CFM rating.

- Then scroll over to the left column to see what the recommended nozzle size is.

Most manufacturers suggest to then select the next size smaller because it will eventually open up to this size. That way you will get more life out of the nozzle as well.

What Bore Size will Work with my Abrasive Grit Size?

My calculations show that most bore sizes will handle most abrasive grit sizes but not all, so please check out the chart.

However, a large grit size used on the smallest possible bore size may be more prone to clogging in comparison to a small grit size with a large bore size. In the case a large grit size such as 54 used with a small bore size of 1/16″, you may want to decrease the abrasive to air ratio at the metering valve.

That’s a really handy chart (exactly how you said it would be ;) )

..Had been looking for this.. ..thanks much, just acquired a “real” 5hp compressor.

Now the hard part, pressure/grit type/size and pressure ref to specific task, (paint removal, rust removal/surface prep, stone engraving. etc). Mostly experience , I suppose (little to none here).

@Peter, thanks for checking it out!

@ Bruce, yes the preferred PSI can also depend on how hard of an abrasive you are using