I got this recent questions about someone wanting to fill in holes with a sandblaster and thought it was a good idea. So I decided to post the discussion here with suggestions and how you can do it inexpensively.

Hello, I own a craftsman 1hp 3gal. air compressor,the plastic hose is cheap and developed a leak,so I am looking to buy 50ft of rubber hose with couplings. The reason I’m sending this is that I want only to buy minimally now, until I move. I can see great value in having a big air compressor and air tools,my dad had them and my sister took the unit as part of Her and her husbands inheritance. My real immediate purpose is to use a sandblaster or siphon kit to attach to the small compressor I have in order to blast clean sand into woodchuck tunnel/holes. I bought clean sand,not play sand, from Home Depot in 50lb bags first. I used that before for this purpose. However they dug a horizontal tunnel in each side of driveway. I don’t know if they went all the way through both sides,but I want to fill these holes/tunnel with sand and cover so it wont happen again. Do you think I can get away with just buying a sandblasting kit,and use my 1 hp comp? Also will sand I have do or will I need other sand or nozzles or what? Thank you very much for your assistance! Randy

Hi Randy,

Hi Randy,

A 1 hp air compressor sounds a little small to run a sandblaster. But it most likely will work okay for what you are doing with it if you are just aren’t actually abrading anything. It might take some time to fill the hole though regardless of the air compressor size.

In my opinion, if it’s a typical driveway at the width of car, then I would just pour the sand in the hole and pack/ push it under the driveway with some type of long rod. Then maybe put a half bag of concrete on each side to cap it off. If you do it this way, you might have to dig a clearance hole around the driveway.

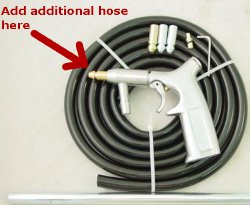

If that’s not feasible, then you might want to check out this cheap sandblaster (http://amzn.to/RO4APq ) which is also shown in the picture on the left. Then you could buy and hook up another cheap tube onto the nozzle. This will allow you to shove it as far down the hole as you can so that abrasive gets way back there. It works basically by sticking one hose end into the sand bag and then hook it up to an air line. This is a siphon unit which you can read about here: https://www.sandblasterinfo.com/equipment/siphon/

Dear Sir,

We are looking for high performance photo-image sandblasting machine for PMMA and PC substrates (0.5-5mm A4-A1 sheets) used in our lighting and signage products. The surface roughening is typically very weak (1-3 microns preferably quasi-prismatic “peaks and valleyes”). Production should be preferably fully automated (scanning nozzle without manual operation). Beads should preferably have micro pyramidal shape – zirconium or silicon carbide) to produce prismatic surface structure.

Currently we use wet etching and/or laser scribing machines ($ 5,000 – 15,000).

Thanks for your help

Dr. Ben Inditsky

I think your best bet would be a 2 axis water jet machine and convert it to dry sand operation?

With correct software and linear actuators it should be possible to get the quality your looking for?

Hello, My name is Shawn,and am into sandblasting and restoring bicycle parts and frames. I had purchased a bunch of different sandblast guns,trying to get the results I needed,only to find out that none of them functioned correctly,and or would continuesly clog or get a pinch in the hose coming from my sand bucket to the gun. I bought,I think, every sand blast gun that Harbor Frieght carried, and also got a few from Amazon, but the gun I liked the best was the gun that Sears sells,that comes with the gun,the black hose and the sand bucket, which is the same gun you show here, on your thread. The biggest problem I had with this gun though, was the inconsistantcy of the flow of sand ! One reason was that the tube comes folded up in the box, and I could never get the kinks in the tube out from when it was folded in the box, another reason, was that the gun didn’t seem to pull enough sand through the long tube,quick enough, so it would have sand come through, then a lond spert of air then sand again. So then I tried to hang the sand bucket, that comes with the gun,in higher above me and the Gun, but then it would kink the line ,because the tube went into the underside of the gun. So then I had an idea, and loosened the Allen screw with the Allen key,that comes with the unit to the front assembly of the gun. And 180 degrees, so the entry tube that the sand enters the gun, was now on top of the gun, instead of the bottom. I still kept the sand bucket hanging, up above me and my project, and this time, I cut and shortened the black rubber tube, to reduce the number of kinks in the tube, from being folded in the box! ( Also on a side note I also purchased a large 21 gallon,125psi air compressor) so I have plenty of flow of air. The problems I ran into this time, was that the rubber tube kept getting in the way, and or, being too short , from shortening the tube, and it was still getting spots of just air, and not sand! I was getting more and more frustrated, so I put my projects aside for about a week, out of frustration and even after spending a lot of money on different guns with crappy outcomes on each one I purchased ! Then one day I was in my garage, with my son, cause he was going with his friends to a paintball place, and asked me to please help him look for his bag paintball guns and equipment. So we were digging through the garage and found the huge duffle bag of paintball Garb! As I picked up the bag, OF COURSE IT WAS NOT ZIPPED UP, and as I lifted it up,all the stuff fell out of the bag and all over the floor! I looked down at EVERYTHING on the ground, and went from being mad at myself to completely overwhelmed with a smile from ear to ear that I couldn’t get off my face! I think my son thought I was going CRAZY, and said, ahhh Dad, are you OK , your scaring me!!! I said OMG, I think I just solved my SANDBLASTING problem!

Laying there, in the pile of Paintball stuff, were a few of the Paintball holding tanks that go on the top of the paintball guns, to hold a lot of paintballs with a hole on the bottom of the tank, that feeds the paintballs into the gun! I took one of the tanks and adapted it to fit on the metal entry tube, which now is on the top of my SANDBLAST GUN ! By doing this, I was able eliminate the rubber tube and the large holding tank above my head, and now have way more freedom with my sad last gun! Now, if it only will work the way I hope it would ! I made a few adjustments, ( I used the smallest nozzle, from the nozzle pack, that I bought, when i purchased this gun from SEARS) and gave it a (SHOT) not only did it work GREAT, but I sandblasted and entire bike frame in about 15 minutes, and before it took me over 2 hours, before I got frustrated and would throw it down! On top of that,I only had to refill the small paintball tank 2 1/2 times! I’m telling you, this is a must try, and on top of that, I used sand from HOME DEPOT ! NOT PLAYSAND, this sand has silica in it, that is very bad to breathe, this sand is an orange/yellow color, and is called DESSERT SAND. ( you do have to dry it and sift it) but once you do, it is the best stuff out there, and is only 4 BUCKS A 50LB BAG! I will send pics to anyone that wants to try this. I also built and awesome collapsible 4ftx6ftx6ft sand blasting booth, that you can stand in, and re use your sand the whole day! Get a hold of me, if you want to see how I built the booth!

@Shawn, thanks for sharing your story and solution. Some of the greatest minds have thought of great ideas based on irrelevant things. I always liked the hopper mounted sandblasters too because of less likelihood to cause flow problems. This may not be in your case, but I have realized some of those siphon hose sandblasters work better with courser grits since there are larger air spaces in between the abrasive for the vacuum to pick up.

You have great ideas. If you want to share anything, we can feature you and your post, then send out a newsletter about it. Thanks