Example of abrasive getting stuck to the side.

Hi Eric,

I have recently bought a blasting pot from ebay, the 10 gallon orange one shown in a picture on your website, I am having abrasive flow problems and wanted to modify it to rectify the problem, I understand that you do a manual on how to fix this problem, the only thing is times are difficult these days and because of the recession and being an artist £15 for the manual is over my budget so I was wondering would you just be able to e-mail me the abrasive flow problem fix for £5? I can pay you via paypal, I don’t need the whole PDF just a solution to fix the flow problem? Is that something you might be able to do?

Kind Regards

Maz

Maz,

I’d be glad to help. What I have been finding out is the first 30% of abrasive is not sufficient because of the poor sandblaster design.

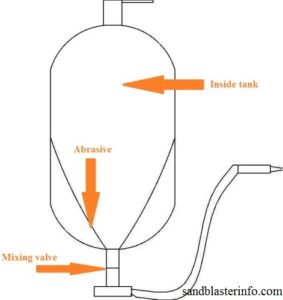

Please try filling the abrasive to at least 50% of the tank size and let me know if that fixes it. This is one thing I discuss in the ebook but there are further details on making it work with less than 50% abrasive. It’s a shame how these are designed, because a lot of the abrasive sticks to the bottom side of the tank and doesn’t get funneled down to the valve properly.

Let me know. Thanks

I bought a dam preser pot from PA years ago, it has sat in the corner for years,<No dam good, and it is always pluged up, tried over sizeing the mixing Tee, filling 50 the 75 % full, took the tip off replaced it with a 1/8" pipe niple seem to help some, but still no hell, I think some day I will cut the bottom open and build a cone and a large mixer Like I use to use when I worked at Can-Car, well that was a 2" hose, and when your co-worker hit you in the ass with it WOW you new it!!!

haha- yea those hoses hurt.

I have thought about building a cone inside also but never got around to it. Sounds strange though.

Is the abrasive getting wet or is the tee hooked up right? I remember when I first put my tee together, I accidentally place the abrasive part in the back. I couldn’t believe I did that. Didn’t even realize it until after a few times blasting. Dooh!

Buy the book, Eric is trying to make a living.

I bought it even though I’m unemployed and unable to find work (British, living in Florida)

Don’t know what exchange rate your using, $19.99 is 13 quid on today’s conversion rate

Forgot date, Feb 19th 2013

Some thoughts from an engineer on cheap pressure pots:

The old adage goes like this: Price, service (or availability), quality. Pick any two.

Invariably, price is the first factor. Availability is the second. Those pots are absolutely EVERYWHERE. Given those two factors, quality is the odd man out…and everybody can testify to that fact.

In order to engineer something inexpensively and SAFE, the tanks must be generously proportioned to handle the pressure and that means elliptical or spherical heads (and this includes the tank bottom). They are draw formed (stamped) from a single piece of sheet steel and then both halves are welded together. Yes: the large, fairly flat bottom makes for a very safe tank…but at the expensive of flow.

Looking at the conical bottom of an expensive pot like Clemco, Schmidt or Empire, you’ll notice annular rings on the outside surface of the metal. The cones are “spun” from a piece of sheet steel, much like a clay pot on a potters wheel. The metal is thick, and the inside of the cone is relatively smooth. The steep angle of the conical bottom exceeds the abrasive’s “angle of repose”. In simpler words, the abrasive HAS NO CHOICE but to fall to the bottom due to gravity and that’s why expensive pots work.

Conical bottoms are expensive to produce, and due to their shape, they MUST be thicker than spherical or elliptical tank heads due to the immense amount of pressure it must endure.

This is going to sound bad, but as an engineer, I would caution you NEVER to weld any pressure vessel. EVER. Companies that produce expensive pots spend millions (perhaps billions) of dollars for special welding and testing (X-ray, chemical, magnaflux, hydrostatic, etc). They also pay high wages to specially certified pressure vessel welders.to do the job right.

And as for propane tanks…

Used propane tanks essentially have compromised (contaminated) metal once they are filled. Their initial welds will always remain good because the metal was new when it was first welded together. But by re-welding on them, you’re expecting too much from “dirty metal”. The propane essentially permeates the molecular surface structure of the metal, and thus causes poor (dangerous) welds.

I’m not saying that it’s “impossible” to weld a used propane tank. People do it all the time. BUT the dangerous consequences are very real. I would be willing to bet a million dollars that ANY mechanical engineer worth his or her salt would agree to the statements I have presented. Anything less is a death wish waiting to happen, and I’m sure that’s the last thing you wanted to hear.

With that said, I don’t expect you to publish this on your forum. But don’t say that you haven’t been warned.

Jay B.