Note: You can now purchase and download the sandblaster plans here.

First off, I wanted to thank all my visitors and newsletter subscribers for coming to my site about sandblasting, glass etching, and car restoration.

There have been a lot of people asking me how I made my own sandblaster so I have been working on creating plans for pressure pots the last few weeks so others can do it as well. In the next few days when they are completely finished, they will be offered here through my site. You can see a rough picture of the homemade sandblaster below before it was painted below:

I have packed these plans with a lot of great information which I believe answers all questions that people have been asking me for the past couple of years. This includes information with bonus topics that cover:

- how to pick out the right air compressor for my needs

- explanation on the different types of air compressors

- expanded information on abrasive & design problems

- and sandblasting safety.

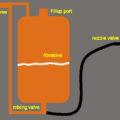

On top of that, I included information on how to make my inexpensive and favorite sandblaster nozzle which you can see in the picture. It shows you sources of where to get the materials and pictures of all the steps.

The reason for this post is that I wanted your input and for you to ask any questions you have. I will try to answer them below so please leave a comment and I will do my best to help. This helps me as well because it shows me what information people really want to know. Then I can take that input and make these plans extremely helpful for everyone.

SO please leave a comment and questions below! Thanks

Hi Eric, I am beyond frustrated with my pressure pot system. I got your plans for the perforated tube on the inside of the tank, implemented it, but it still seems that all I am getting out of the nozzle is air. I used the new system and got a few seconds of encouraging etching but then it seems to have clogged up again. I took it apart unclogged the fixture again, fired it up and same problem. I am at my wits end and ready to I-don’t-know- what! Please tell me what I am doing wrong. Compressor dials read right, dial on pressure pot reads right so I don’t think the problem lies there. It seems to clog immediately. HELP!

Need info on sandblasting trainning ir clases email me ir call me at (954)798-4677 my name is Elvis

Thank you Eric for the info. I would be interested in a blaster nozzle that was thin enough to fit down the neck of a wine bottle, or at least inside of a bottle whose top has been cut off (about the width of a large drinking glass), then delivers the abrasive at as close to 90 degrees as possible in order to etch the glass on the inside of the bottle. Are you aware of, or have you created anything like this? Thanks again for the info.

-RT

Barbara, did you get my email before about the bad designing of a lot of pressure pots?

I am still thinking that the pressure pot isn’t filled up with abrasive enough. Also, what abrasive are you using and grit size? As long as a water separator is on there it should work.

Ron, I haven’t made anything like this yet since I haven’t needed one. I remember sending you some sources but they were kind of expensive. Also check out a website called Mcaster Carr. Thanks

Hi Eric

thank you for let me know the latest up dated information

i am looking foreword for this plans , i still yet didn’t built it.

this new plans will reduce a lot of time and errors and prevent me to be frustrated like Barbara

thank you for sharing this information

thanks

Good Day all.

I am Shaun Zeeman from Walvis Bay Namibia, would like to start the sandblasting bussness, have to. we do not have this tipe of exuipment in Namibia, I do have to buy all equipment from other countries, I would like to do sandblasting on GLASS and also STONE.

Am planning to build plast pot from plans – “Erics Plans”

Is their anybody out their that can give advise on materails and equipment needed to do the sandblasting on glass and stone – will be appreated

Thanks Shaun

Do you have an approximate cost estimate to build your “DIY Sandblaster”?

Thanks

We have an unused new SCM system that we are not going to use. Comes with a compressor also. Ready to make a deal. New it was $3500 range.

what is a scm system, i’m interested in sand blasting glass but have little knowlege about equipment and cost i’m looking for affordable equipment not to build a shop, just part time hobby and any information to find the right beginnings

thank you

robert rohrer

A guy in Chattanooga bought and picked up our system yesterday. Sorry. Thanks for the post here. Good luck. David

Thanks for keeping us updated!

Dear Eric

Your site looks very interesting.

I have a sand blasting company in Thailand where we use pressure pots (abrasives) on the big stuff

and siphon type (abrasives & soda) on smaller & softer stuff.

We also use high pressure cleaners with sand intake on very heavy duty jobs where the wetting

factor is not an issue.

I was searching info on :

a) how to modify one of my abrasive pots to work with soda.

I’ve seen companies that sell an ‘upgrade’ that is basically a modified mixing valve

http://amzn.to/Ui4Ng3

but, of course, they don’t explain how it works.

Its cheap , so cheap that if I made one myself it would probably cost me more, but still, I’m always

reluctant to purchase anything if I don’t know how it works.

I’m in Thailand so, as most of the suppliers of technology & parts are in the US or Europe, there’s nobody

here locally that I can visit or call to come & explain or show or teach us how to operate new stuff.

We have to do it on our own by trial & error.

b) dustless blasting (that doesn’t make dust but still has the (wet) media disposal problems of course)

This looks really good , on Youtube at least, but does it have any drawbacks ?

I have nowhere to go and see anything in real life here as nobody is using this system.

> I see they use Holdtight 102 mixed with the water to get a longer rust-free window in between

the blasting & the base coating.

I think I can use this product with my high pressure cleaners with sand intake as well, as we face the

same rust bloom problems because of the water residue in the nooks & crannies.

> They use abrasives that look similar to the pot abrasives.

I use quarry quarts sand that is plentiful & cheap & very ‘sharp’ if compared to river bed sand,

& don’t bother to reuse as I sell it to a company that makes cement articles.

I sometimes use garnet that is imported from India, also relatively cheap, but this we need to

recycle at least 2-3 times until its too contaminated to re-use.

But what is the advantage of this system if compared to the high pressure cleaners with

media intake (and added Holdtight 102) ?

If you read info on the Holdtight website, they clearly state that less water with more pressure

will give a better penetration into nooks & crannies & a better final cleaning result due to the

greater mechanical action on the treated surfaces. http://www.holdtight.com/?p=48

The pressure of a pot is 7~10 bar ? No comparison to 200 Bar of the pressure cleaner.

There are also cost saving in usng less water , with easier area cleanups.

The pot will deliver more volume of air at a lower pressure than the high-pressure cleaner

With the pot, the slurry/water mix is adjusted into the air flow as needed.

The pressure-cleaner delivers no air …. Is this where the difference is ?

Also, what is the difference in the “dustless” pot system using water/media slurry

http://dustlessblasting.com/

compared to the water induction nozzle system applied to the nozzles of ‘dry’ pot media blasters ?

http://www.contracor.eu/abrasive/nozzles/WBT.html

> In the ‘dustless’ pot, the slurry/water mixture is dosed into the air flow.

The ratio water/media needs to be dosed upon filling the pot

(because of different specific gravity of the media & the water, I’m not sure the ratio will be consistent

during the emptying of the pot, not to mention the thixotropic effect, especially with fine media)

A) It is then only possible to adjust the ‘fixed’ ratio of water/media into the air stream while working.

B) It is only possible to shut the slurry feed & use air alone during work with this system.

> In the dry pot, the water is dosed into the media/air mixture at the nozzle.

A) We can dose the media ratio into the air with the bottom mixing valve & we can also dose the

amount of water to the air/media stream. All three ‘components’ of the stream can be adjusted.

B) It is possible to use : air/media + water

shut the water flow & use only air/media

shut the media flow & use air + water (to do final rinses with Holdtight 102).

shut the water flow & use only air to dry the blasted parts

Many more ‘real time’ dosing possibilities.

And less silica dust with the water induction nozzle system :

See pages 2 3 & 4 of this pdf http://www.cpwr.com/pdfs/Heitbrink.pdf

Not to mention the pot & parts cleanup.

> With the ‘dustless’ pot, they recommend emptying the pot & washing the slurry circuit &

long tube etc, every time after use, otherwise the water/media will clog. (thixotropic gelling)

check the end part of this video https://www.youtube.com/watch?v=PiILNQGj9Vs&feature=related

> With the dry pot, I never empty anything unless I need to change the mesh/type of media that I’m using.

If we use the water induction nozzle, we just clean the nozzle & venturi. Done.

In the Blastgreen BG-100 video , they mention that the 2 x 175 litre tanks will last about 6~7 hours.

https://www.youtube.com/watch?v=PiILNQGj9Vs&feature=related

That about 1 litre per minute.

The pdf document http://www.cpwr.com/pdfs/Heitbrink.pdf states on page 4 that the

slurry is usually 80% media+20% water.

If it uses 1 litres of water/minute, does it use 4 kgs of media per minute ? = 240 kgs per hour ?

Advertising on a few ‘dustless’ websites states that tyey save between 20~30% in abrasives media cost.

How is that possible ? We can’t re-use the media (I re-use garnet 3~4 times) so the saving are not there.

Where are they ?

But most importantly. isn’t the blasting power & end result the same if the 2 system are compared to each other ?

Have you seen these dustless blaster in operation ?

So sorry for going on & on, but all these questions keep buzzing around in my head & I was wondering if

any of your manuals cover these topics.

Pls let me know so I can go ahead & purchase one or both.

Thanks for listening

Best Regards

Ivan Valle

+66844336780

Italtech Co.,Ltd.

> Bangkok Office Address

DS TOWER 2

126/93 Sukhumvit Rd. Soi 39 (Pobmitr)

Klongton, Wattana, Bangkok 10110 Thailand

Tel +66-02-6620689

> machinery factory Address :

28/52 Moo 19, Bangpleeyai, Bangplee,

Samutprakarn 10540 – Thailand

+6684-4336784

> metal works factory address :

1017 / 14 Moo7 Bangpoomai, Muangsamutprakarn,

Samutprakarn 10280 – Thailand

Tel – +66-02-7090039

Hi Ivan, thanks for the comment.

I am surprised that you would think making a soda conversion would be just as expensive. Just by looking at them, you can see how to make them. These cost $140 and I am guessing you could probably make one easily for 30- $40. I was going to write up plans on how to make them, but in my honest opinion, I’d rather just buy a separate soda blaster. It would be a real pain trying to clean out all the abrasive when switching.

The smaller ones cost about the same, but I don’t know how much the more expensive the larger ones cost. I’d probably just make one if it costs a few thousand dollars.

As for the dustless blasting- sorry, I can’t help you there. I am not familiar with dustless blasting.

Eric, I built one very similar to this myself a few years ago. I can not see but do you have an air control valve in the pipe going to the bottom of the pot down the side?

I wish your video is Closed Caption for the. Deaf

I inherited a “San-Blast” (most of label is gone, i think name is correct)pressure pot blaster, it has the large white ceramic tips and a large lever valve at the nozzle end. Also inherited a HUGE real 5hp compressor. I do believe I need a new hose for the output side, (large) seems about an inch in od, possibly bigger, do you have suitable replacement, I could not find one on your site. ..also if anyone has a manual that they could copy, could you ref this post to Eric, perhaps I could pay for a copy.