Manual & Fixes

At last, ways to start sandblasting on a budget that actually works well and fixes abrasive Clog Problems!

–Save Time, Frustration, & Money

Pressurized Sandblaster Mods- Step by Step Instructions to fix Inconsistent Abrasive Flow and where to get a Low Cost Pressure Pot while being effective!

Have you ever bought a cheap pressure pot sandblaster or are thinking about buying one? Well, if you have, they will save you a lot of money but they have abrasive flow problems. This sucks, but it can actually be fixed quite easily in 30 minutes or less.

The problem with these is they don’t have too bad of quality for the price; really it isn’t that bad. What is bad about them is the design and I show you step-by-step plans of how to easily fix this problem with a few cheap materials that you can get at the hardware store.

So before you buy equipment, you will want to read this manual of where to save money off these inexpensive pressure pot sandblasters and most importantly, how to fix their inconsistent flow problems.

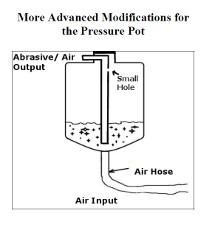

The picture shows my easily modified inexpensive pressure pot that has smooth flowing abrasive, even with very fine abrasive grit.

Inconsistent flow problems are one of the most annoying things about a sandblaster that can really be easily fixed. So if you have recently bought a pressure pot or are looking at buying one, learn how to fix the problem and save yourself a lot of frustration.

The investment in this info. will not only show you how to save the money but how to make your system as effective as possible. So before you think about buying an expensive blaster, you will want to read this information. I’ll show you:

-

Multiple sources to get inexpensive pressure pots at different sizes.

Multiple sources to get inexpensive pressure pots at different sizes. -

How to easily make them from an okay piece of equipment to a great smooth flowing sandblaster.

How to easily make them from an okay piece of equipment to a great smooth flowing sandblaster. -

Low cost sources for add-on appliances such as an dead man valve.

Low cost sources for add-on appliances such as an dead man valve. -

Guide to other creative things you can do with your pressure pot.

Guide to other creative things you can do with your pressure pot. -

An attached version of the Sandblasting 101 ebook which talks about all types of sandblasters, abrasives, & how each sandblaster works

An attached version of the Sandblasting 101 ebook which talks about all types of sandblasters, abrasives, & how each sandblaster works -

NEW: More Advanced Modifications for the Pressure Pot

NEW: More Advanced Modifications for the Pressure Pot

My manual guide is available in a PDF file. Acrobat Reader is required to open and view the file. If you don’t have it, you can download it free on the internet which I will show you.

There is no shipping fees and you will be directed to a website where the PDF file can be downloaded.

I will be giving this information away at $19.99 for a limited time and then will be selling it with my main course for double the price due to its effectiveness to allow people to have a good working system and save them money.

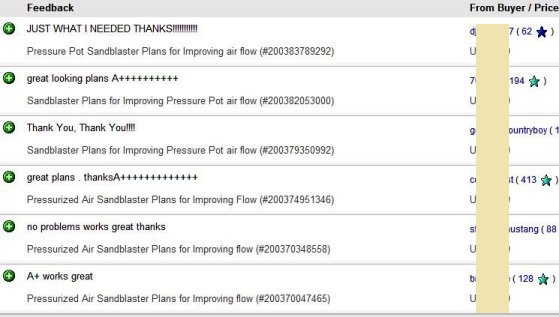

So far I have only got positive feedback from customers (on another online shopping site). See the snapshot image I took from my profile below:

But there’s more. I made some drastic changes since the time I sold it on other shopping cart stores a while back. Now I have included:

- Information for beginners.

- Basic information about the different types of equipment.

- And which type of blaster is right for your needs.

- An Air Compressor Guide.

Next, you will be able to instantly download it by clicking the button below.

100% Risk Free Guarantee:

If this resource didn’t provide you with any helpful information and you aren’t 100% satisfied with the Ebook, then send me a quick email and I’ll happily refund you in full within 60 days. This way you have no risk in getting my ebook!

Hi Eric. Do you have any info on diy. machinery to make your own crushed glass blast media?

I have been doing quite a lot of net surfing & have come to the conclusion that glass seems to be

cost effective & very productive and very cheap if i can perfect a machine.I dont see it to be a great challenge but a few pointers in the right direction would be helpfull..

Thankyou

@ Rowland- it sounds like an interesting idea if you have a large source of scrap glass, but I don’t really deal with making my own media.

One thing to think about though- you should not use glass that has a lot of silica in it, which is just about most common glass found. It would emit an extremely high amount of deadly silica dust upon impact. The professional stuff that manufacturers sell is an inert glass with little to no silica in it.

I am interested in building my own Dustless wet media blaster, not the kind used with a pressure washer–the kind that uses an air compressor and mixes the abrasive and air before pushing it down the line. Do you have plans for such a blaster?

Thanks-Keith

@Keith, I have been building one of these and testing it to perfection, but the project has been delayed lately. I will let everyone know once the plans are up. Thx

Iam a welder by trade and have discovered by heating painted metal you can clean paint off really easy with just a small propane torch.

Is it possible to use heated air and hot sand to remove paint and rust?

@mikey, I am sure there is a way– maybe by directing a flame to the pressure pot, but it might warm up the seals too much. I discussed something similar here https://www.sandblasterinfo.com/sandblasting-thick-paint-off/ where you can direct a heat source to the paint first.

i am safety officer can u explain when sand blasting conducting time what types of hazard we face.

I finally got my siphon Harbor Freight (HF) blast cabinet unit put together, complete with some mods [lights, additional “breather” tube next to siphon tube, foot control (locked ON for now since i am using the HF trigger gun), platform with casters, HF air separator with regulator and gauge, Ridgid 6 gal vac with added drywall bag for dust collection].

But I am having severe inconsistent flow problems. When I pull the trigger, the siphon hose fills up in a couple of seconds, the gun plugs up, and media flow stops. Sometimes if I pulse the trigger it will continue to sputter out a bit. I can block the nozzle and pulse to backblow the siphon hose and start again, only to have a couple of seconds of media blow. I have worked a couple of hours on my first part, cleaning up a floorboard for my tractor, but still only have it about half done. I have been experimenting with different nozzle tips, removing/putting back the added breather tube, moving the added breather tube outlet in relation to the end of the pickup tube, modifying the added breather tube to a narrow slot exit, adding more media, increasing pressure, and of course fixing blown off HF hoses and other maladies that occur while i learn.

I am using the included Harbor Freight gun, nozzles, and siphon tube. I am using some (garnet i think) abrasive I had lying around from an old tumbler project (AmberBlast, which seems to be no longer available). My compressor is a Sears oilless 6HP/33 gal rated at 11.5 SCFM@ 90 PSI. I have a 3/4″ copper overhead air piping system necking down to a short 3/8 drop with a quick disconnect near the blast cabinet. I have noticed no moisture in the air or media. There is a (about) a 1/2″ 30ft flex hose with quick disconnects between the drop and the blast cabinet. I have tried pressure settings (set at the cabinet regulator) from 80 to 110 PSI or so, and at least two sizes of the nozzles (i cant tell if there are three sizes or two as one nozzle seems to have a slightly oval hole).

I am going to try some other possible free “fixes” including going to lower pressure (i read one post online that garnet works better at about 60 PSI and should run as low as 40). I will try removing the extra breather tube as well with lower pressure settings, and check that my stock HF tube has some airflow for breathing (it looks like the two tubes are a tight fit).

I will upgrade the gun, change media, add a mixing valve, or other mods if i can somehow figure out these are legitimate fixes for my problem. But i don’t want to spend much on “plug and try” fixes that might not be effective. When i know i can get it going, i will invest in some silicon carbide media as most of my work will be rust and paint removal from steel.

I have researched around and found mention of U shaped pickup tubes with side holes, and both home-made and commercial media mixing valves with air/media mix adjustment. There are too many variables and i don’t have infinite time and $ to try them all. And it is frustrating that some people report the stock HF components work adequately, which makes me think i dont need any more upgrades, just tweaking the right variables.

I could not tell if, or which, of your online ebooks might reveal the solution(s) i need. I am willing to invest if you are confident one of them will do the trick for me, or if you could give me some diagnosis steps, I would be willing to try them.

Eric,

Got your ebook and it has solved a few of my problems ,however you say you have now added a list of vibraters and where they can be purchased . Do I have to buy a new book or can I just purchase the up dates? You have been a light at the end of the tunnel on so much. Keep it coming! Thank you , Michael

@Mike, thank you for your purchase! You do not have to purchase it again. I will send you an email shortly with the download. Thanks!

Can you tell what kind of 1/4in tubing I should use

I want to know if l can connect the pressure pot to the compressure machine for inflating car tyres

@Tim Jones, in the ebook, I included a direct link to where to get this inexpensively, but I can’t remember it off the top of my head. I tested many types and this stuff rocks for its ability to resist abrasives!

@ATMann, I guess you are thinking of those portable air tanks. Yes, you can definitly make one of those, but I wouldn’t suggest you use it for blasting and blowing up tires. Even after you remove a lot of the abrasive out and pull air from the top of the tank, you still might get abrasive coming up. Best to have two different tanks.

hi Eric..!

I confused when I will to buy the silica sand for sandblasting

because I don’t know to choose it .( I’m Newbie)

Please let me know.

how do I choose the silica sand with measuring unit in mesh

I will to do removing paint include thick body filler of my old car (VW Kombi)

thank you so much

I have read somewhere here tonite about you having an adjustable nozzle, ok you got my interest…where and how, also I will purchase the above guide tomorrow.

My BIGGEST problem with my pot was (after long and laborious hours) MOISTURE…made all the adjustments, drained the pot TREE times…..but I did not actually clean out the pot !!!!, Took all apart back flushed…thought that was good…………NOPE Apart again, used a long stick with a rag attached to the end and cleaned out the complete inside, again back flushed…. WOW, just dump and fill really did nothing. After cleaning out the above way….I bet you I had probably 5++ lbs on the tarp of semi damp..really hard to tell, sand, left apart a couple of days to dry out.. Now I use an electric heating pad wrapped around most of pot, and add less sand in pot, adding when needed. I reside in Canada…very hi moisture content, even with a dehumidifier in the shop WHAT A LEARNING EXPERIENCE….

Looking where I can take sandblasting classes in upstate NY? I live just outside the Syracuse Area.

Eric,

Thank you for the offer, but thing are just too tight at the moment. Here a photo of my first go in thirty years.Did this yesterday.

Regards

Attachments area

Preview attachment Glass.jpg

[Image]

Thank you for the manual on fixing the problems with pressure pots. I found it clear and very useful. I have a couple of questions:

1. Why do you leave the top end of the stand pipe open? If it extends beyond the level of the media in the pot, would not all the compressed air in the tank rush through it and into the hose without carrying any abrasive?

2. I need to switch media types in my HF pressure pot every so often. What is the best way to flush out any remaining media in the pot (before making your stand pipe modification) and what is the best way if I go ahead with the stand pipe modification. I suspect your are going to say, “take the connectors off the bottom of the tank and let it drain out” — if so can you recommend any sort of quick release for these connectors.

Thanks.

heyy i need a help in sand blasting pot has a problem of abrasive flows,i don’t know how do it,please can you help me or shows me.

thank you

robinson

Does your ebook on sandblasting tips, modifications and info go into detail on the specifics of where and what to buy for the needed sandblasting components (I.e.pressure pot, compressor, nozzles,etc.?).

I have a cabinet but am really lost about selecting my other components since there is so little information out there for putting a complete system together.

We have an Eastwood Econoline Model RA-36-0031 that is not blowing the blasting material in to the cabinet, although the air is reaching the Abrasive Control Valve. We are completely new to this, so I apologize if my wording off.

Can you help with ths?

thanks

Col

Hi I bought your book 2 and the first day I opened it and it should me how to put a tube in it for better flow. I payed with paypal but now I can’t find it in any of my files. Could you check to see if you received payment my files show a payment

Thanks Jerry

Jerry, I am looking into it now and will send you a private email. I can send you all the download files. thanks!

Eric

I am manufacturing aluminium windows & doors and iwant to do my own design s on the glass

Howd’y Eric, I’m still looking for advice about what would be the best material to remove paint and plaster from cinder block to prep an old house for demo. Thanks for letting me know that you did get my message/question. ✌

Where i will get send blasting training center in benoni

Hi

Eric

I have question can email me? personally about sandblaster build. Thanks Paul

Hi, I am looking for the best way to get into sandblasting, easy to understand and affordable, way to refinish my old cast patio furniture. Obviously this is your product/course/info, but is it appropriate for a newbie? Thanks W

i bought your how to fix abrasive flow and it didn’t download. Can you send please?

I corrected my email, only one j

@Jerry, thanks for your order and for letting me know. I will send it via email shortly. As always, the receipt email has the download link as well in case anyone misses the download after ordering.

Thank you!

Eric

Do you know where i can buy the stands for glass display

Hi Eric, I bought the how to modify book several years ago and did the mods but really need to re-do them ‘better’ as I didn’t drill enough holes in tube plus didn’t realise at the time I probably could have used a coarse mesh instead? It’s been so long since I downloaded book I’m not sure if I got update? Don’t know if you have record of it fr4om about 10( )yrs ago? Haven’t even looked at blaster since I started looking after grandson 2+ yrs ago but he’s eventually going to be into everything when I start teaching him more as he gets older (only 3 at present) He already wants to help (my turn, my turn) and knows what screwdrivers are for, maybe he’ll be a mechanical engineer/astronaut one day, he says he’s going to the moon (LOL)

@Peter, this is good to hear! I am not sure which version you have, but I will email you the latest version.

Thanks

Hi, I’ve been dry blasting for some time whilst restoring motorcycles but want to move to slurry blasting to give a better satin finish on alloy cases. Have you any ponters on design for a DIY cabinet because commercial offerings are seriously expensive for DIY use.

Thanks in advance.

Seems I’ve reached an impasse with my 40lb pressure pot. The 2’ 3/8” 10 mm 250 PSI hose for Pressurized Abrasive Blaster is not available. I bought a whip line from TP Tools but the threads are different. It is a CENTRAL PNEUMATIC® which I got from Harbor Freight and they can’t get a replacement. A good reason to not buy from Harbor Freight. I was going to buy a 5hp 220 compressor from there. After buying everything I need to start etching I can’t go any further. I’m thinking of forcing the hose fitting ends I bought or maybe rethreading it. When I originally put it together a couple years ago there was no problem with attaching it to line couplers. Strange this one hose is the only fittings on the pot that are mm. Any suggestions?

Thanks, Michael

Find PIRTEK, they will make any hose you want. (or any other hydraulic/pneumatic specialist) HF does discontinue stuff, I had same problem with lathe but modified a larger motor much cheaper than getting ‘correct’ one (from 3/4hp to 1hp ‘continuous use’)

You can have cheap and reasonable (HF) or pay a lot more for convenience .Pirtek won’t be cheap but is all over USA and Europe

What Is the coarsest grit you would recommend in the pressurised pot system I want to remove old paint from pitch pine beams in my house

I have already purchased this book. Do I have to purchase it again to get the new updates??

@Dustin, thank you for your order. No, you don’t have to purchase updates- I will send emails through our newsletter when there are updates.

HELLO – Can you be of help to me??

I bought a 110psi sandblasting pot from Harbor Freight. Can’t seem to do any blasting with it however. Constantly stops feeding the sand through the mixture valve at the bottom of the tank. I am feeding it with 110psi thus very frustrating to do anything with it. I have two moisture filters installed one at the compressor outlet and the other at the inlet of the pot. I am wondering about some mention about the adjustment valve at the bottom of the pot feeding 90 deg into the air stream. Is this good or bad? in some ways I don’t think there is anything too wrong with this. But why I am wondering does it stop functioning there?

I am not sure your manual can help me much since everything I have put together should work it seems. But still willing to order your manual but if I feel it is much to simplified and does not provide the answers I need I would like to get a refund pronto. Is this agreeable with you?

Lee

Hi, i have exactly the same Problem on my 45 liter Sand blasting pot. I am feedind my Sandblasting pot with 3hp, 50 liter, Double motor quiet Compressor. I also made changes on the T /piece, and changing it with a Half inch T/Piece for better Sand flow. Also changed the whole Ball valve to a bigger 1/2 inch Ball valve. The sand is dry, and still finding a problem wit the Sand floww to my Gun, Could you please help me with the wrong Settings, Regards, Allan, Gonubie.

I need some information on th Settings on my 45 liter Harbour Freight Compressor, Tegards, Allan Fourie Gonubie