The problem most people have is that they already have a pressure pot and don’t want to buy an additional soda blaster. So here are some tips on converting a sandblaster into a soda blaster. And as asked by a visitor, you can make a soda blaster from my plans by adding the part suggested here.

Buying a Conversion Kit

Before I get into the steps on how to convert it, as I discussed in this post before, you should first know that companies sell conversion kits here: http://amzn.to/wyCBSz.

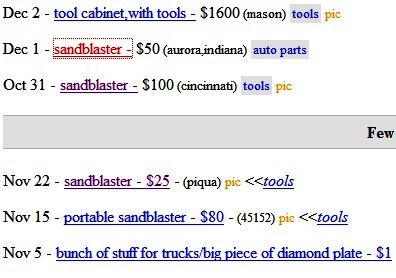

I don’t know why these kits are so expensive because you can make them yourself easily with a few inexpensive parts. I think I even saw them for sale on Harbor Freight for about $20.

Modifying the Sandblaster into a Soda Blaster Yourself

If you look at the conversion kits and read the instructions, all they are is a replacement assembly abrasive valve with a slightly smaller diameter. And they have another valve with a hose perpendicular placed inline before the abrasive valve. They call this the purge valve which is suppose to be opened when there are clogs and is used to drain the soda abrasive. Manufacturers recommend soda abrasive to be drained when you are done using it since it shouldn’t be left in the tank for long periods of time and can “cake” up.

If you look at the conversion kits and read the instructions, all they are is a replacement assembly abrasive valve with a slightly smaller diameter. And they have another valve with a hose perpendicular placed inline before the abrasive valve. They call this the purge valve which is suppose to be opened when there are clogs and is used to drain the soda abrasive. Manufacturers recommend soda abrasive to be drained when you are done using it since it shouldn’t be left in the tank for long periods of time and can “cake” up.

My idea to convert your current sandblaster into a soda blaster as shown in the picture is to simply install a NPT pipe tee before the abrasive valve and add another valve to the side with a tube. Although I haven’t tested this yet, I believe the larger size of the valves on the current sandblaster is irrelevant.

If you’d like to try this or find that the soda abrasive works best with the smaller valves, please leave me a comment below. Thanks and feel free to ask me any questions.

Did you manage to test this setup?

So my instructions never describe where to connect to my compressor?

Hi, my son thinks that he can buy a H F 110lb sand blaster and just add soda abrasive and it will work. Will it work well? What is the purpose for the so called conversion kit? Thanks, Art

@Art, I believe the blasters made for soda blasting are better- they are designed differently for very fine soda materials, but you can convert.

What size of the tee and hose is needed for soda coversion? Obviously it is far cheaper to buy the pieces but need to know the size of piping and tee for soda conversion from regular tanking media.

Garry

Eric, Have been reading your blog for a couple of years now. Getting ready for more blasting as the weather improves here on the east coast I hope. I have a HF blast cabinet that I use for smaller parts, and have been using crushed glass, the results are unbelievable! It has saved me at least $400.00 over buying replacement parts for the MGA I am restoring. I also have a small soda blaster(HF), but am thinking of upgrading to a larger one. Your article was perfect timing. One question: I would like to save $ on the blasting media. I’ve read the cautions about sand. Do you think it is safe enough to use sand in a pot blaster if I use the correct mask, goggles, and blast outside? I thought about “Black Diamond coal slag, but don’t know what my back yard would look like afterward. Tried to get a MSDS, but no reply. Look forward to your articles.

I have a three hundred pound sandblasher pot with dead man switch . The hose is a big hose with 3/8 tip tell how can convert it to sode

I am really new to this kind of stuff. I do know the difference between soda and sand blasting but I have no equipment yet. I plan on working on wood furniture and metal furniture. I just don’t know what I should buy sand was hoping you could point me in the right direction. I see your hand held gravity blaster; I assume you need an air compressor to operate it? If that’s the case I don’t know what size of compressor I need! I am so glad I found your articles! Help! Everything I read is a bit head of my knowledge…