Hi Eric, Just got your ebook on building a pressure pot and I have a few questions. How do I know What PSI the pot is working at? Can I fit the water trap to the pot? Also does this pot have the same flow problems as the other pots you talk about, and if so do I have to purchase your other book to fix this?

How does the pinch clamp work, if I drop it in the open position does it stay open? Do you have any video of the pinch clamp in action? How does the nozzles fit into the hex cap? Do they simply slide into the hole you drilled? The one in the picture looks to have a sleeve or something over the nozzle.

I read that you may be working on a PAB style gun, any word on that? Thanks for your time. Derek.

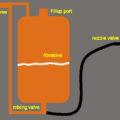

After this step shown in the plans is completed, you can begin adding the pressure gauge and air trap here.

Hi Derek,

Thank you for the purchase. Some air compressors have a pressure gauge that allows you to adjust the pressure going to the pot. But it is nice to have one on the sandblaster also. So you would have to modify one on with the correct size couplings and pipe nipples- I suggest using a tee.

The Pressure Gauge

You can find some on Amazon here: http://amzn.to/AkPSR3

The Water Trap

The water trap can be added the same way also and some units come with the water trap and pressure gauge like this one: http://amzn.to/ADUacF

About Abrasive Flow for Home Made vs. Store Bought Versions

You don’t have to get the other ebook unless you have further problems. Read the bonus on page 34 should prevent any flow problems. I found that these homemade sandblasters actually have better flow than the cheap units sold by companies such as Harbor Freight, because the inside surface is smooth. If you look at the inside of the harbor freight ones, you can see the sides are very rough causing abrasive to bind to the sides.

Pinch Clamp Type Sandblaster Nozzles

For the pinch clamp, you can leave the valve open and stop the flow by pinching the clamp. Its very nice for something so inexpensive. No video at this time. Most nozzle tips are tapered so the front slides through the hole and stops at the other end. You just have to drill the hole a little bit smaller than the back end of the nozzle.

The hex cap in the picture is just an extra one I took from my other harbor freight unit. It just looks nicer with the sleeve but isn’t needed. I have made a PAB style gun but haven’t perfected it yet. When I do, I will share info on it. Standby.

Thanks!

Question? Got a free Craftsman 12 gal. air compressor.Can this be used at all for a small

pressure pot or micro blasting?

3.7 SCFM @ 40 PSI

2.6 SCFM @ 90 PSI

125 MAX. PSI

2 HP

The size of the pressure pot doesn’t matter. What does matter is the size of the nozzle that you use.

I suspect if you use a small nozzle such as a 1/16″ or 3/32″ then it might be sufficient.

But you would have to use this chart: https://www.sandblasterinfo.com/air-compressor-chart/ and do the math if possible because it doesn’t list anything below 1/8″.