It seems like sandblasting wine bottles is a popular topic that people have been looking for so I figured I would create this quick guide on how to sandblast wine bottles. I included a bonus in the sandblaster plans manual which also talks about this. Its actually very easy to do and the hardest part is cutting out the stencil.

First, you need to grab a wine bottle that you want to sandblast and peel off the paper label with a knife. Some labels are hard to get off. One way to make it easier to remove is to soak the bottle in warm soapy water so that it softens up. This makes the adhesive and paper label easier to shave off as seen below:

Second, you need to make sure the surface of the wine bottle is clean. I like to use rubbing alcohol to remove any excess glue residue and any oils from your hands. This ensures the surface is clean. Now you can start on the stenciling process.

Third, start by drawing or transferring a black and white pattern onto a sheet of sandblasting stencil material such as vinyl or contact paper. If you use contact paper, you will need to use light blasting pressures and a fine abrasive grit so that the sandblasting media doesn’t penetrate through to the glass in areas you don’t want it to.

The stencil design can be pre-cut first or cut after the stencil sheet is placed on the bottle. I found that it is usually easier to place the stencil sheet on the bottle first and then cut out the design, but it depends on the process. In this case, I pre-cut the stencil as you can see below. I simply cut out the design by following the lines with a sharp knife such as a hobby knife or razor blade. Once cut, you can pull the areas that will be etched with the sandblaster in the following steps.

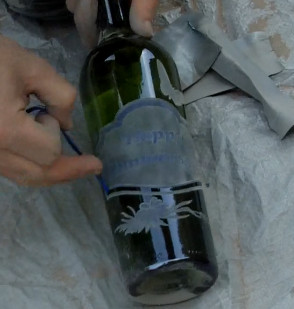

For the fourth step, align the stencil onto the bottle and smooth it with something flat. You can use a plastic putty knife or a vinyl material applicator. Also, mask off the outside of the stencil with a strong tape. If you use regular masking tape, you might want to double or triple it up so that the abrasive doesn’t go through.

Once your all set and ready, all you need to do is sandblast a few inches away at a desired PSI until the wine glass bottle is etched to a desired depth as shown below. The higher the PSI, the quicker and deeper the sandblaster will etch into the glass but 30 PSI should do just fine for most folks. I used my homemade variable pressure nozzle which was explained in the member’s area here.

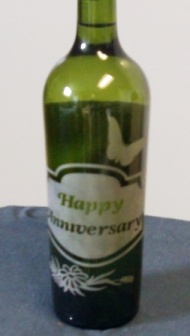

After the wine bottle is sandblasted to a desired depth, remove as much of the stencil off with your fingers or use a knife to peel off. Then, rinse the bottle off with water.

What sandblasting equipment do you use? I have a compressor and want to try my hand at this but dont wan to spend a fortune getting started? Is that possible?!

hi I urgently need to sandblast a bottle. can you may be help me out?

Louise, sure I’ll help. What questions do you have?

What kind of vinyl do you use so that the sand does not go through it while blasting. Or does it go through anyway? Merry Christmas 😉

Very straight forward info on bottle blasting. Here in Hawaii we have abrasive material derived from lava. I will have to do some research to find out if it has silica in it. Seems like if it doesn’t, it might be good to use in a sandblaster. Regards, John

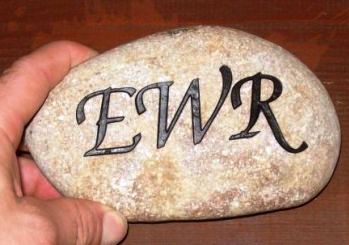

eric; i have been lover of rocks and stones my whole life. i have done many split stone stone projects,fireplaces,wall,raised garden beds ect. I am blessed to have tons of stones to work with on my own place. i have seen sandblasting signs in bolders and small patio projects and i looking to gather information to do more with rock and stone. i hope that sandblasting signs ,glass ect. is not a dying art as splitting natural stone and building some thing that last a life time. i know that to be good at something it take time ,and patiance something i’ve learned with 40 years of work with stone. i know that a pressure pot system or pressure cabinet it the way to go. Do you recommend to buy new or buy seperate items used to get started and add as i go. I am thinking of renting a large mobil compressor and pressure pot to try some blasting outdoors this spring using silca sand. Will that cut into stone or should i just wait till i get a reclaim cabinet and use different media. what size air commpressor inside building should i go with i have 3 phase available here and have seen what i thought was good buys on used factoey units. I would love to hear what you started with and things that you brought used and should have brought new andwhat you would now different now looking back when you started. i think you willingness to share is great as i’ve done so with my talents over the years. keep up the great work and inspireation to help others . mark

what kind of sticker you using for sadblasting in wine botells

i would like to know what machine of modern teqnology do you use for the design of the labels you want to sandblast on the glass.

Willie, there is a few different ways you can create stencils. Some of the modern ways are signage cutters, photoresists, and laser cutters.

I would like to purchase equipment o do wine bottles and windows

can I use the same compressor for stone carving and glass etching, if so any good suggestions

Chris, of course you can. You just need to make sure that the compressor has a high enough CFM for a higher pressure when stone carving. Stone carving is usually around 60 PSI and etching is usually around 30 PSI.

Guys I am selling the exact equipment to sand blast wine bottles, rocks, glass etc. My wife and I bought the SCM Jet Stream Two to use in a business, but our product is carved by manufacaturer. It is unused, brand new out of the box. It includes recommended hoses, filters, moisture traps and photo developing kit that makes the blasting film. I can email photos if interest. We are in Franklin TN. Paid over $4000 for the whole kit, but make us an offer!!!

nashcourier@yahoo.com

David,

I thought I emailed you before, but if not- if you write up information on the system and include a photo, I will post it on the site and ask all my subscribers.

Let me know. I’d be happy to help

What are using to develop your vinyl stencils? I am using Accuart film then develop onto a photo resist . Find this a little expensive as I have to get the accuart thru the U.S. Is the vinyl stencils any less expensive and what type of equipment is required????

Debbie

Hello, thank you for the tutorial!! what kind of sandblaster do you use, and what sort of compressor does it need? I am a first timer, and no one else will answer my questions 🙁

I just need to know what kind of sandblaster and what kind of compressor to get – what else am I missing? Thank you so much!

FOR A STENCILE, YOU MIGHT WANT TO TRY THE PHOTORESIST. YOU CAN BUY DIFFERENT THICKNESS’S FOR, GLASS, WOOD OR STONE. YOU HAVE TO “DEVELOPE IT JUST LIKE A PICTURE AND A NEGATIVE BUT IT IS VERY EASY. THE SHEETA ARE 8″X 14” AND COST $7.OO PER SHEET. YOU CAN TAKE PICTURES WITH YOUR CAMERA, OR TAKE PICS FROM THE COMPUTER TO BLAST ON THE GLASS…GIVE IT A TRY

Eric,

I am interested in sandblasting just the edge of the bottle after it is cut – such as cutting off the top of the wine bottle to make a ‘glass’. I have tried sandpaper, much too slow. I also tried a grinder, but I got very bad results. Any suggestions?

Thanks!

Dale

This sounds like a good idea. I am just now learning how to sandblast utility trailers. Maybe later I willytthis.

David Keith

Eric,

What if you have 100 wine bottles all with the identical pattern, would you have to make 100 stencils or is there a way that you can get away with using just 1 stencil?

Thanks,

Bob

Bob, yes you can make a reusable stencil by using mylar sheets and cutting them out with a hot knife cutting tool. You would have to make the stencil different though so that there are no “stencil islands” which gives it more of a blocky appearance.

Or you could have the stencil cut out of a metal material from a laser cutter. Some local sign shops might be able to do this or you can order it online. I have seen a few places on the web that do this before.

Hi Eric thanks for all the info it helps a lot.

Thanks

Leon

Eric I want to know what kind of vinyl is good for sandblasting a river rock and how to keep the stencil from coming off the rock when sandblasting

where can I buy the whole sandblasting unit-air fliter, hood , blasting pot- and anything else.

great info Eric, much appreciated,not too sure about the mylar( coating. comment about multi stencil for wine bottle) is it to protect the stencil for multi use?

was wondering if I was using contact paper for my stencil and cutting it out on my cricut could I just double or triple my contact paper to make it a thicker mil. that would be 4 to 6 mils I’m supposing?? if at that thickness, what could I blast (glass, stone, pavers, wood) and at what psi? Thanks

Theresa:

You can get 12 mil sandblast mask from uscutter.com. 15 inch wide by 10 yds long that I use on my vinyl cutter. It is suitable for wood, glass,plastic & stone. It should work on your Cricut also. It sells for 19.95 + shipping. I use about 30 PSI for wood or stone ( pressure blaster), less pressure for etching glass or plastic.

Eric I like this concept. After our discussion before regarding vinyl cutters I think this is the way to test the market so as not to spend a lot of money on capital equipment that does not return its value over time.

Thank for all you information very helpful

Again thanks. Tony g

DEar Eric

Gas (Petrol) is very good solvent for many chemical glues, it goes through paper & dissolves glue very easily & then you can remove label easily, without scratch of knife, Very nice information, keep it up, appreciate your inspirational efforts

Thanks

Great article, I have been Abrasive Blasting in Australia for over 25 years, now in Singapore mainly HPWJ, but I enjoy reading your site! Started off in Historic Building work, bricks timber and so on. Keep up the good work!!

Hi Eric, Thanks for all the information you sent me, and the information about the wine bottles peaked my interest because we make glasses, vases, bird and humming bird feeder out of wine bottles. It would be nice to sandblast something on them instead of them being plain. Thanks again.

Hi . could you please tell me what you would media grit you would use on glass ,rock and wood .can the same

on all

This is wonderful, thanks very much for these tutorials but what are the stencil made of?

hi eric just wondering if you can tell me were to purchase 8mm blasting mask and also aluminium oxide 180 grit please love the bottle etching by the way keep up the good work

Hi Eric I have just purchased a 40 Litre sand blasting unit, I am using a 10 horsepower comp. I am having a lot of trouble with medium flow it works for a very short period of time then stops or flows a solid stream of medium. all of the medium has been dry. I am at my witts end.

Regards Hamish

Hi,

Once a bottle has been sandblasted can it be be cut with a table top scoring,heat,ice method?

Thank you

@ Michelle, you can indeed cut it that way, but I would suggest cutting it before sandblasting. Depending on how deep you etch it and how close it is too the cut, it is possible for it to break where it is etched too.

I have been sandblasting glass and stone for a few years now and am interested in sandblasting wine bottles. My biggest question is regarding the removal of the wine label. What are the legal restrictions, if any, of removing the label from a purchased bottle of wine in order to blast a custom graphic on it.

thank you

Henning

How can i post my picture of my wine bottles job?