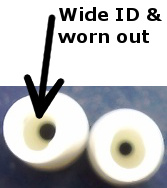

Examples of two different types of carbide nozzles.

I’ve discussed the different materials manufacturers use to make tips here. As you may recall, I also mentioned that there are at least 3 different types of carbides used. But first, let me explain why carbide nozzles are important for many of you.

If you blast with aggressive abrasive such as aluminum oxide or silicon carbide, you really should be using a carbide nozzle tip. Most folks working in glass etching and rock blast engraving, fall into this category. Carbide nozzles may be a good idea if you work will slightly less aggressive abrasives, as long as you blast frequently. That way you may never even have to replace the tip!

Problems With Low Quality Nozzles

- Quick nozzle wear which has to be replaced frequently.

- Causes a waste of time in stopping in the middle of a project to replace.

- And it is actually more expensive replacing many inexpensive nozzles which equate one high quality nozzle.

- Loss of blasting power. A cheap nozzle (such as ceramic) will wear out quick, sometimes within a minute which will ruin your blasting power if your air compressor doesn’t have a high CFM output for the worn out, enlarged nozzle.

3 Carbide Nozzle Types

Listed below is the 3 types of carbides that are available today, along with their estimated service life when used with aluminum oxide abrasive:

- Tungsten Carbide– this is the lowest priced and the least durable of the carbides. It is estimated to last for 20-40 hours of sandblasting time.

- Boron Carbide – a higher priced carbide with significantly more service life of 200-1000 hours.

- Composite Carbide – this is typically slightly more expensive of the carbides but has a significant service life of 1000- 2000+ hours. It turns out that it is the best value in terms of cost per hour of use.

The 1/16″ ID ROCTEC nozzle tip inserted into a nozzle gun.

Which Carbide Do I Recommend

In my opinion, if you plan to sandblast for more than a years time, I would recommend you get either of the top 2 most durable nozzles: Boron Carbide or Composite Carbide. Since composite carbides can last up to 5 times longer than boron carbides, I have always been a proponent of composite carbides. The good thing is, they aren’t 5 times the cost! A composite carbide can sometimes cost 1.4 – 1.9 times the cost.

Composite Carbide Nozzle Brand: ROCTEC by Kennametal

Depicts the three sizes available for the ROCTEC.

When I first started sandblasting, I utilized the typical ceramic cheap nozzles for my pressure pot. About 4 years ago, I eventually got tired of them wearing out and started looking into other solutions.

I heard many folks recommend that it was almost a necessity of getting a composite carbide nozzle, manufactured by Kennametal called the ROCTEC.

With lots of praise of this new composite nozzle technology, I went ahead and spent $180 on this nozzle. I must say, it was the best money I ever spent on my sandblaster. Still today, I am using the same 3/32″ ROCTEC nozzle and haven’t had to replace it yet! I’ve run high blasting pressures through this nozzle upwards of 100psi with aluminum oxide abrasive ranging from 220 to 60 grit.

Where to Purchase ROCTEC Nozzle for Discounted Prices

Since I am such a fan of these nozzles, I have now become a distributor for Kennametal’s nozzles and am offering them to you folks at lower prices than other retailers. I am not sure how long I will keep them at these prices. You can get these in 3 different sizes for $129.99 here.

Awesome great information Thank you

Good info, I wasn’t even aware of composite carbides although I did know boron carbide is much harder than tungsten carbide. Is composit more brittle that boron carbide though? It would suck to spend $130 only to break it if dropped

@ Peter, in my experience they are durable for how hard they are. Maybe at least as durable, if not more than the other carbides. I’ve dropped mine on the concrete floor 2 or 3 different times and never had a problem. That is a good point. Similarly, I was wondering the same thing as I went to pick it up, but they seem to be very durable.

how do i send you a picture